The idea of a tread drive wheels wheel isn't new – ancient civilisations like the Mesopotamians, Egyptians and Greeks used them to move heavy things around and to assist with powering equipment. These original tread wheels were wooden, and were frequently worked by slaves or animals. Another important aspect was the waterwheels designed during ancient times, since that was what drove the wheels when working.

In the industrial sector, tread wheels are used on equipment like conveyor belts and assembly lines to facilitate the work of moving products down the production line. They are also used in construction machinery, like crane and bulldozer, to carry and transport heavy materials to the required location. Wheel treads have of course permitted materials and goods to be moved faster and more efficiently than ever

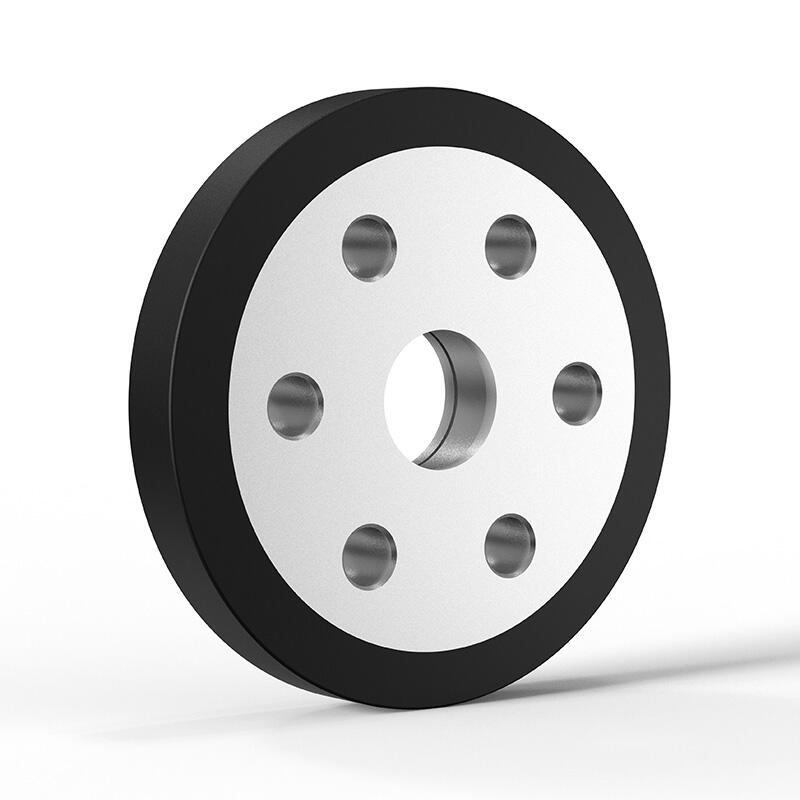

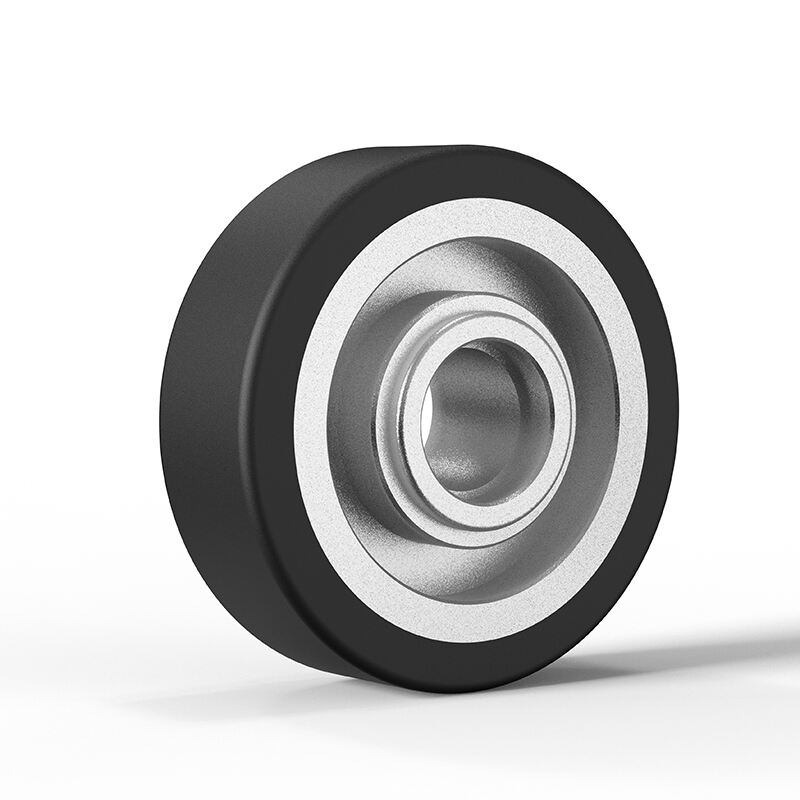

Tread wheels operate by friction between the wheel and a hard surface to rotate around an axle. This rotation may be provided by a motor or engine, or force may be generated by a human or animal moving the wheel. The wheel is configured with treads to lend traction to capture and move along a surface along which the wheel is turned and engage and move the wheel in a forward or reverse direction.

Tread wheels work because they are very simple machines which are very good at shifting heavy objects, or powering devices with minimal effort. They are designed to ensure equal weight distribution and provide stability, which makes them suitable for many different purposes. Tread wheels are also adaptable and can be employed in a variety of applications such as vehicles, agricultural equipment, construction equipment, and manufacturing processes.

In the manufacturing sector, tread wheels are employed in equipment like conveyer belts and assembly lines to facilitate the movement of items in the production line. They are also found in construction equipment like cranes and bulldozers to help hoist and move hefty materials when and where needed. In agriculture, for example, tread wheels are harnessed to drive farming tools like tractors and combines, and can enable farmers to harvest crops more effectively.

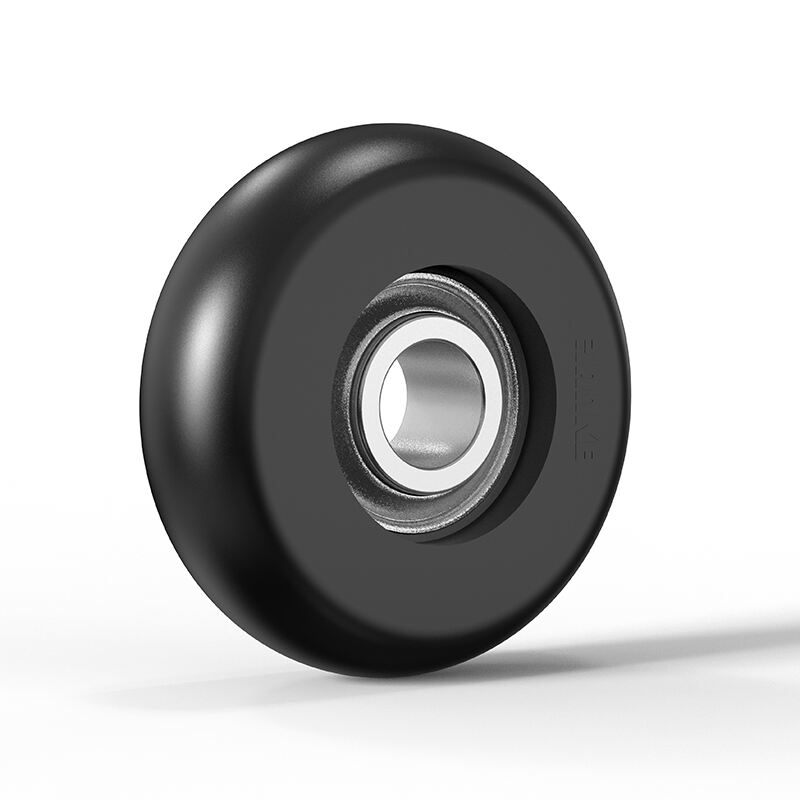

Improvements in materials and manufacturing technologies are also resulting in tread wheels that are stronger and stronger, and can be used under even the most extreme conditions and high loads. New types are also developed to improve performances, efficiencies for many industrial sectors. Tread wheels will remain an important facet for transportation and manufacturing for many years into the future – and an inescapable part of our daily lives.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.