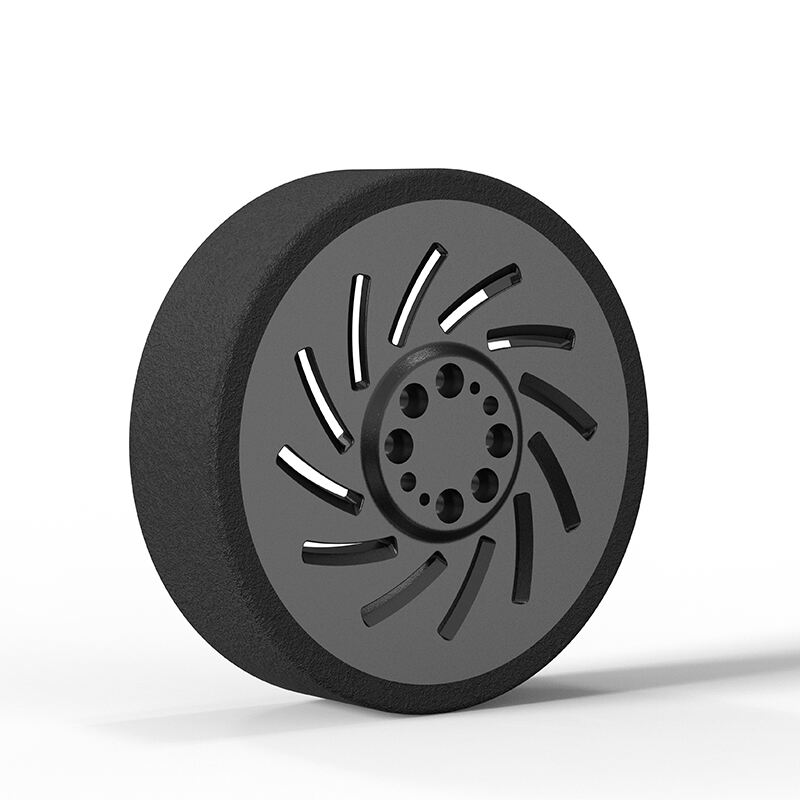

Hey kids. How do those cute little robots—one of which we caught a glimpse of in the video — known as AGVs glide around so fluidly? And it’s all thanks to something called the drive wheel., we’re going to find out more about the drive wheels in AGVs and how they help these robots whizz around the warehouse? The drive wheel is typically constructed of a high-traction material, such as rubber or polyurethane, for minimal slippage and good traction on the floor. This makes the AGV run smoothly even on wet, uneven floor. The motorised drive wheel is then controlled by the AGV’s control system with location instructions.

Without the drive wheel working properly, an AGV would be unable to move around. That’s why it’s so essential to ensure the drive wheel is working well at all times. The wheel drive is the "heart" of the AGV, which enables it to move forward and follow a track. Ever see an AGV whipping around a warehouse and wonder, how does that thing move so effortlessly? Can you believe it's all because of the drive wheel? The traction between the drive wheel and the floor, as well as the rotation direction of the drive wheel, guarantee the AGV to transfer efficiently from one site to another.

More recently, AGV drive wheel is improved with sensors and cameras, which can be used to perceive the environment of AGV. Such sensors are capable of detecting obstacles on the path of the AGV so as to regulate movement of the drive wheel in order to prevent collision. This leads to further improved AGV-safety when handling various products in a busy warehouse.

So even the finest drive AGV wheels can hit snags now and again. “He says the most common problem they typically encounter is not achieving the necessary traction, therefore the AGV will spin and skid on the floor. This is often a result of adding too much lubricant to the drive wheel, and can usually be fixed by cleaning the drive wheel and ensuring that it’s aligned properly.

Another issue for AGV drive wheels is the wear and tear from working continuously. As time goes by, the drive wheel may wear down and be not good enough to drive the AGV to move. In such cases, the drive wheel can be replaced with a new one in order to maintain performance of the AGV systems.

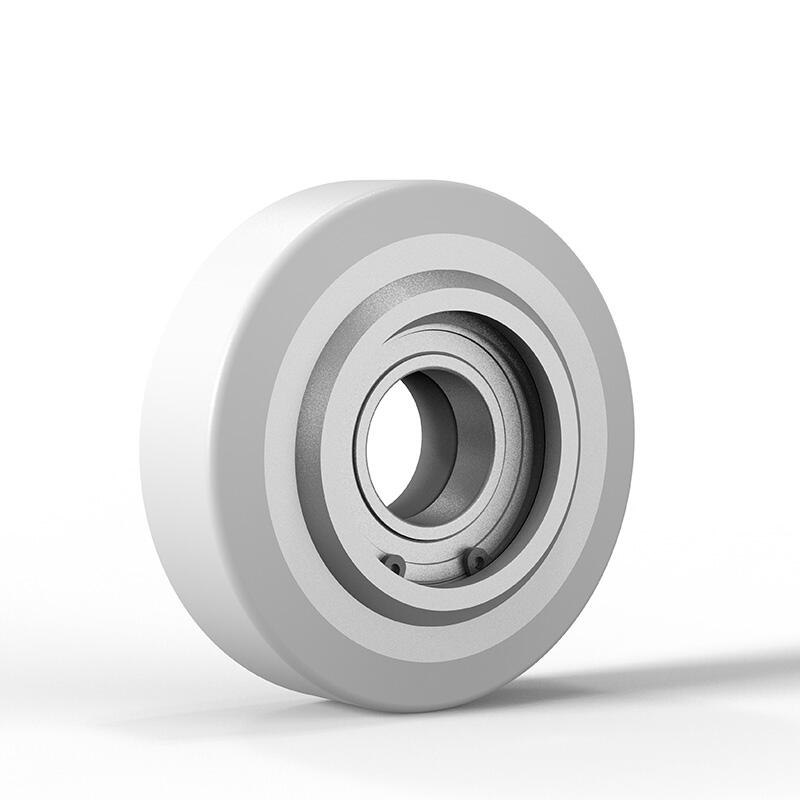

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

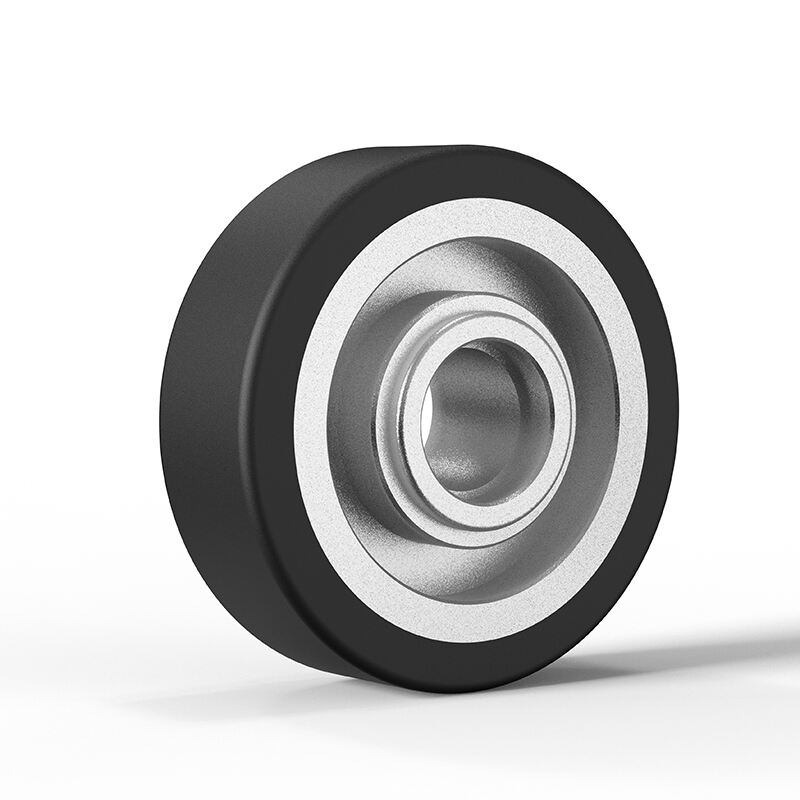

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.