Conveyor rollers, which include urethane conveyor rollers, are crucial for use in many machines and industries, aiding in the movement of things from one place to the other. These rollers from Hanke can be found in factories and warehouses and other areas where things need to be moved easily and efficiently.

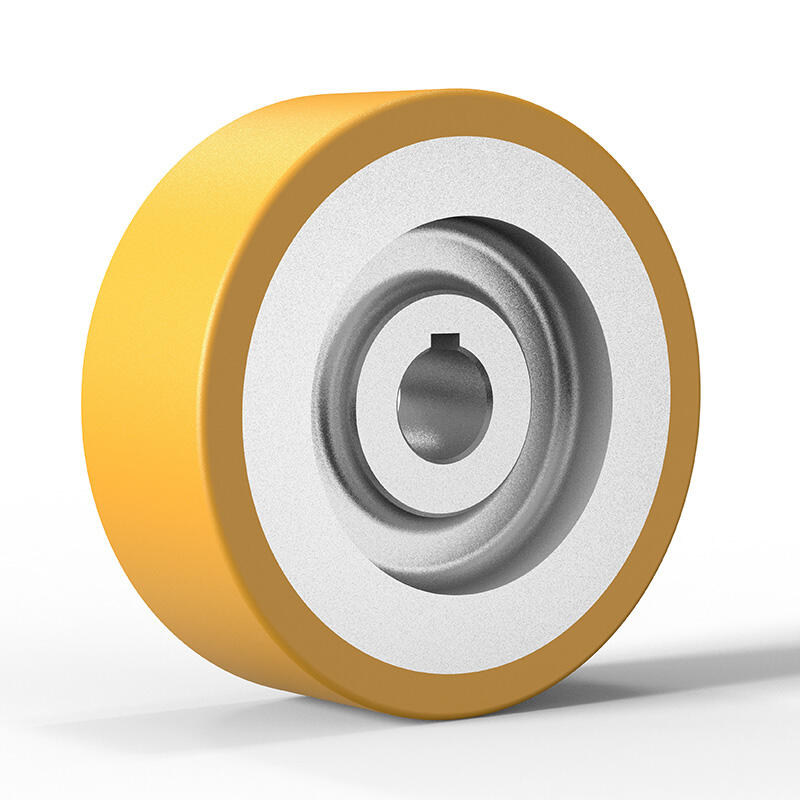

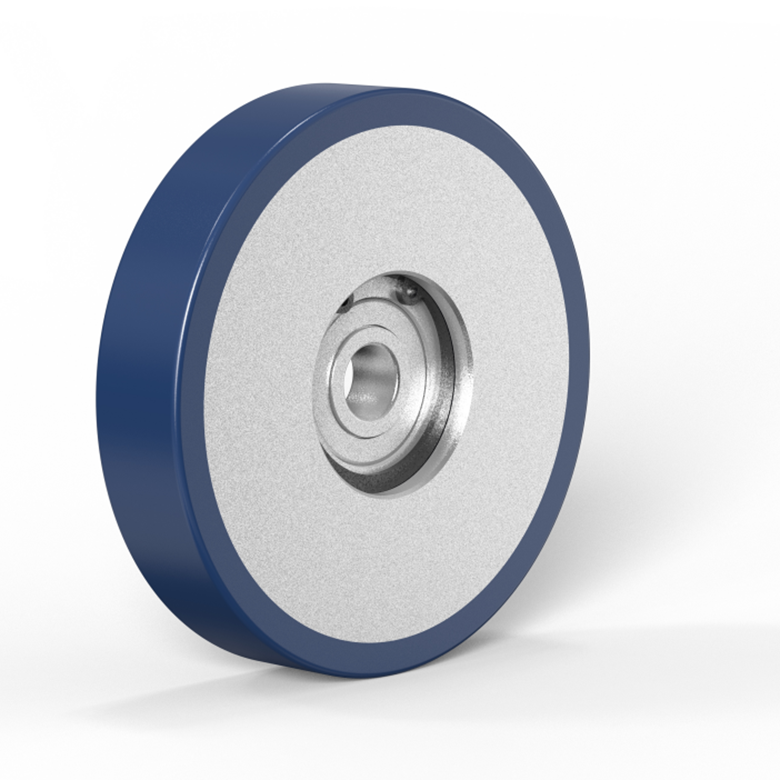

Urethane conveyor rollers are tubular shaped solids that rotate anywhere on an axle to assist movement of products down a for granted conveyor belt. The rollers are constructed of a high-impact urethane which will provide you with many years of heavy use without the cushion wearing down. The rollers rotate as the conveyor belt moves, and the items placed on the belt are transported from one side to the other.

The are numerous advantages of when using urethane conveyor rollers in industrial applications. One of the best things about them is that they really last. Urethane is a hard material that supports a lot of weight without giving or bending. This translates into extending the lifetime of the custom polyurethane rollers so that they need not be replaced frequently, which in turn is a cost saving to companies with the reduced frequency of replacement and associated maintenance costs.

Yet another advantage of the urethane conveyor rollers is that they are able to withstand the chemicals, oils, and other similar items that often are found in industrial settings. Urethane is non-reactive and won't be damaged with these materials, so it is great for use in areas with chemicals and such, such as factories.

There are also some kinds of urethane conveyor rollers that are adjustable, letting a company fine-tune the size and shape of those wheels to suit its specific requirements. As a result of this flexibility, Hanke small urethane rollers are used for numerous industries, ranging from food processing to automotive production facilities.

For clean Hanke urethane conveyor rollers you need to follow regular maintenance. This would also involve keeping the rollers clean at all times by picking out the dirt or debris and prevent for them to deteriorate faster. You would also check the rollers for damage like cracks or worn spots, and replace them if they show signs of damage.

When it comes to selecting the right urethane rollers suppliers for your use, the weight of products being transported and their dimensions, as well as the speed at which they must travel, are considerations that you must take into account. Also, be sure to stay away from a roller that is not made of high-grade urethane because this will degrade the product's strength and reduce its lifespan.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.