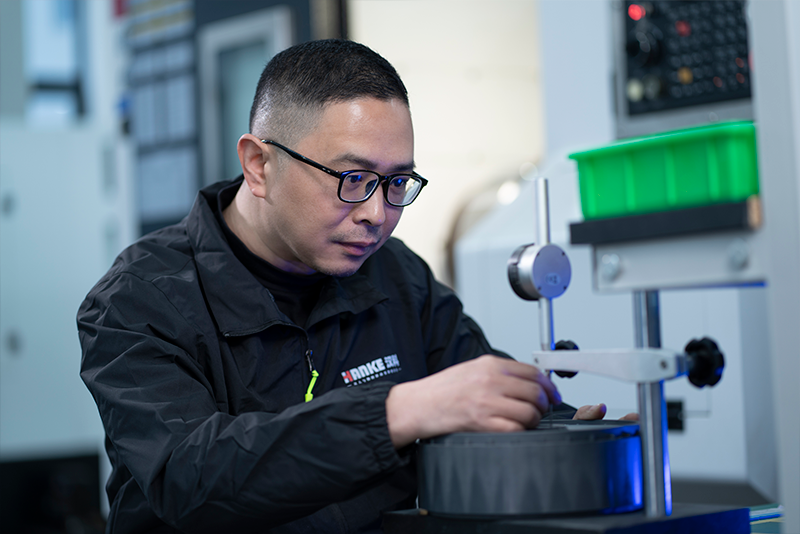

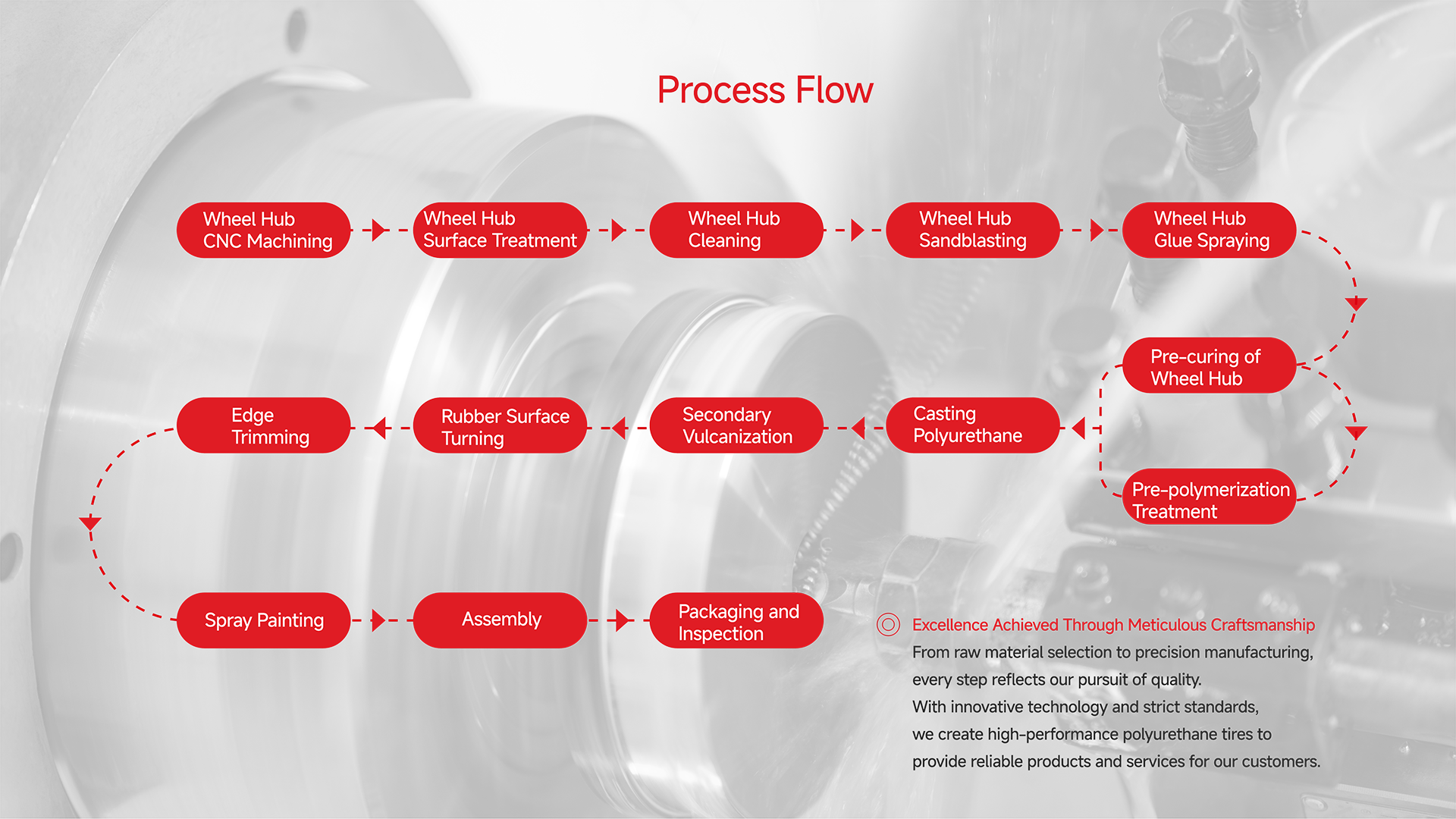

Check whether the processing of relevant dimensions complies with the requirements of the drawings according to the drawing requirements

Check whether the requirements are met according to the drawing requirements

Check whether the oil stains and dust have been cleaned up thoroughly

Check whether the sandblasting distance, rotational speed and time meet the requirements of the operation standards

Check the temperature, humidity and the thickness of the adhesive

Check the temperature of the oven, the actual temperature of the wheel hub and the pre-drying time

Check the temperature of the oven, the actual temperature of the bucket and the pre-drying time

Proportion verification, pressure record sheet, three-piece set of test pieces, first sample, raw material grade verification, demolding time

Check the temperature of the oven, the internal temperature and the vulcanization time

Check the drawings and measure the dimensions

Check the drawings and surface scratches

Hundred-grid test and color difference comparison

Check whether the product labels and packaging meet the order and transportation requirements