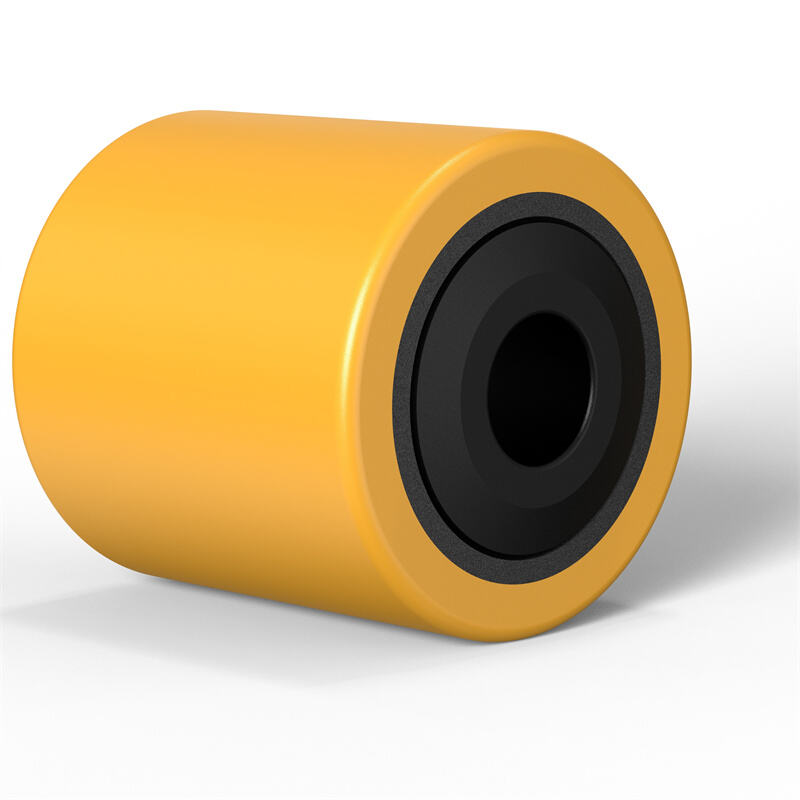

In the case of Hanke AGVs, wheels and Polyurethane drive wheel play an important role in their performance. AGV wheels become the feet of these robotic vehicles, enabling them to move easily and effectively in warehouses and factories., we will take a look at the significance of agv wheels of good quality, how to select the most suitable ones for your needs, and the role they play in improving safety and mobility for warehouse automation. We will also delve into the just-released state of the art in AGV wheel technology and why it is so critical to improving material handling processes.

AGV are more and more widely used in warehouses and factories, and the reason is: they can be used to automate materials handling, make production more effective and decrease human errors. But the robots will only be as good as their wheels. It is important to have great quality AGV wheels to avoid any hitch in the equipment, and maximise productivity.

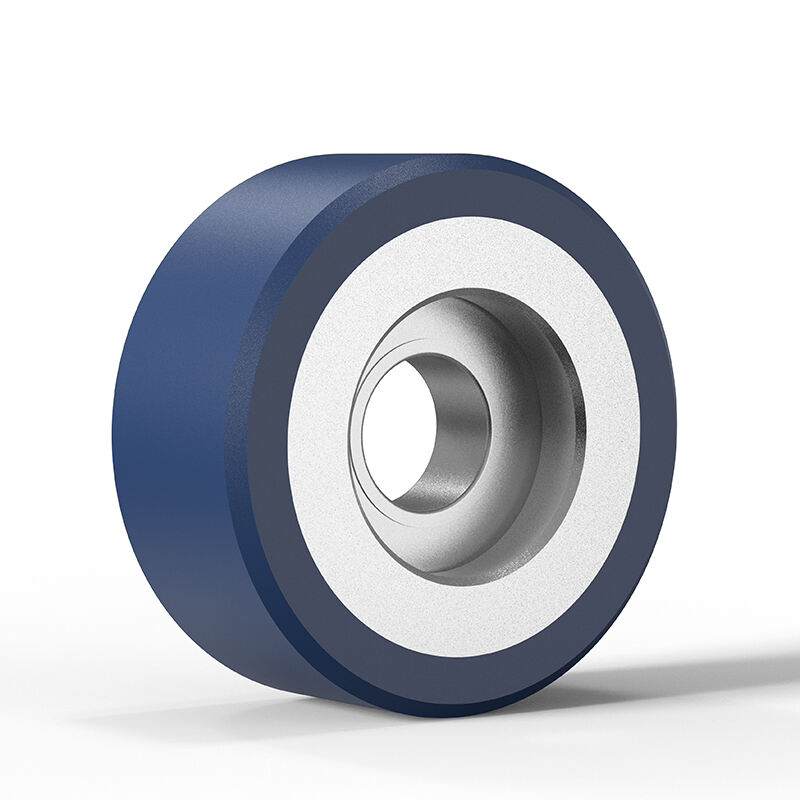

When you choose AGV wheels and Polyurethane Idler wheel for your robots, there are many factors to take into account: load capacity, speed requirements, floor conditions and maneuverability. Hanke provides an assortment of AGV casters that can be used in diversified application scenarios. Whether you’re in need of heavy-duty wheels to haul heavier loads, or those with special tread pattern wheels to add additional traction, it has you covered.

In any warehouse or factory, safety is essential and where you have robotic vehicles playing a key role, AGV wheels are even more important so robotic vehicles can move safely and efficiently. Hanke's AGV wheels and Polyurethane guide wheel are designed to endure daily heavy duty cycle, they are reliable and reduce accidents. Furthermore, our caster wheels have low flex and are easy to maneuver, enabling AGVs to turn tight corners and surfaces with ease.

With each passing technological improvement, AGV wheels and Polyurethane bearing are also advancing. It is working all the time to develop and research-new technology quality of our wheels. Our AGV wheels are constantly being improved and modified by our engineering department for the sole purpose of creating more reliable and efficient designs.

The AGV wheels are important to improve the material handling process in warehouses and factories. With premium AGV wheels and Polyurethane conveyor roll installed, enterprises can automate tasks that are dull, dirty, or dangerous, boost productivity, and cut costs. With the correct wheels, AGVs can operate 24-7 with pinpoint accuracy and greater speed: moving a product from one spot to another.

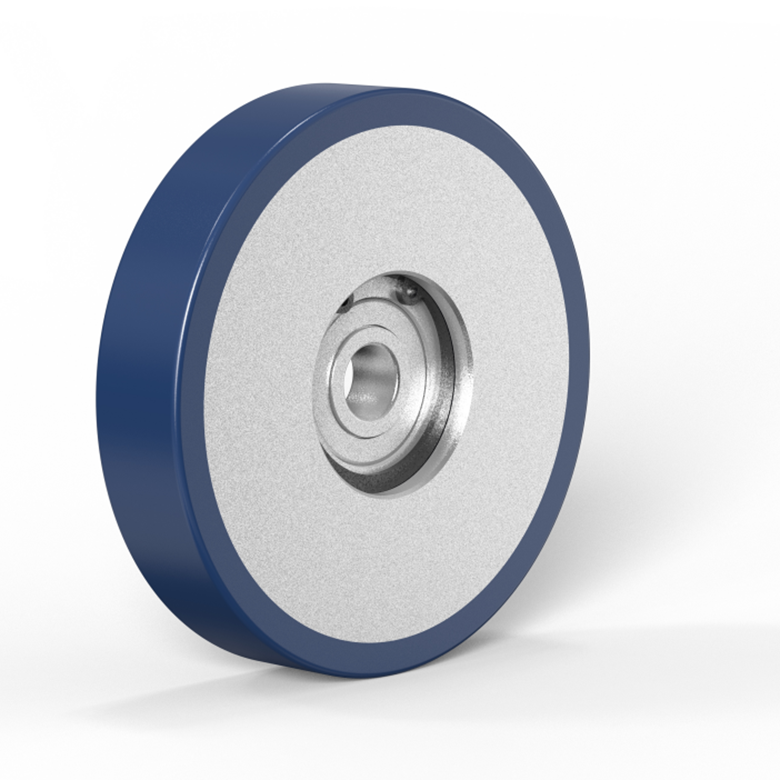

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.