93 Shore A

ok

Very good

Outstanding

Tread: The high-quality polyurethane elastomer cast by chemical reaction has a hardness of 93±3 Shore A, low walking noise, low rolling resistance, protects the ground, is very wear-resistant, has high cutting and tearing strength, is non-marking and non-staining, and has excellent bonding effect with the wheel core.

Wheel core: Metal materials such as 45# steel, cast iron, die-cast aluminum alloy, stainless steel, etc. can be selected according to working conditions; surface treatment can be spray painting, phosphating, galvanizing, Dacromet, etc.

Other characteristics: Resistant to a wide range of corrosive substances; operating temperature: -30°C to +70°C, temporarily up to +90°C, load capacity reduced above +40°C

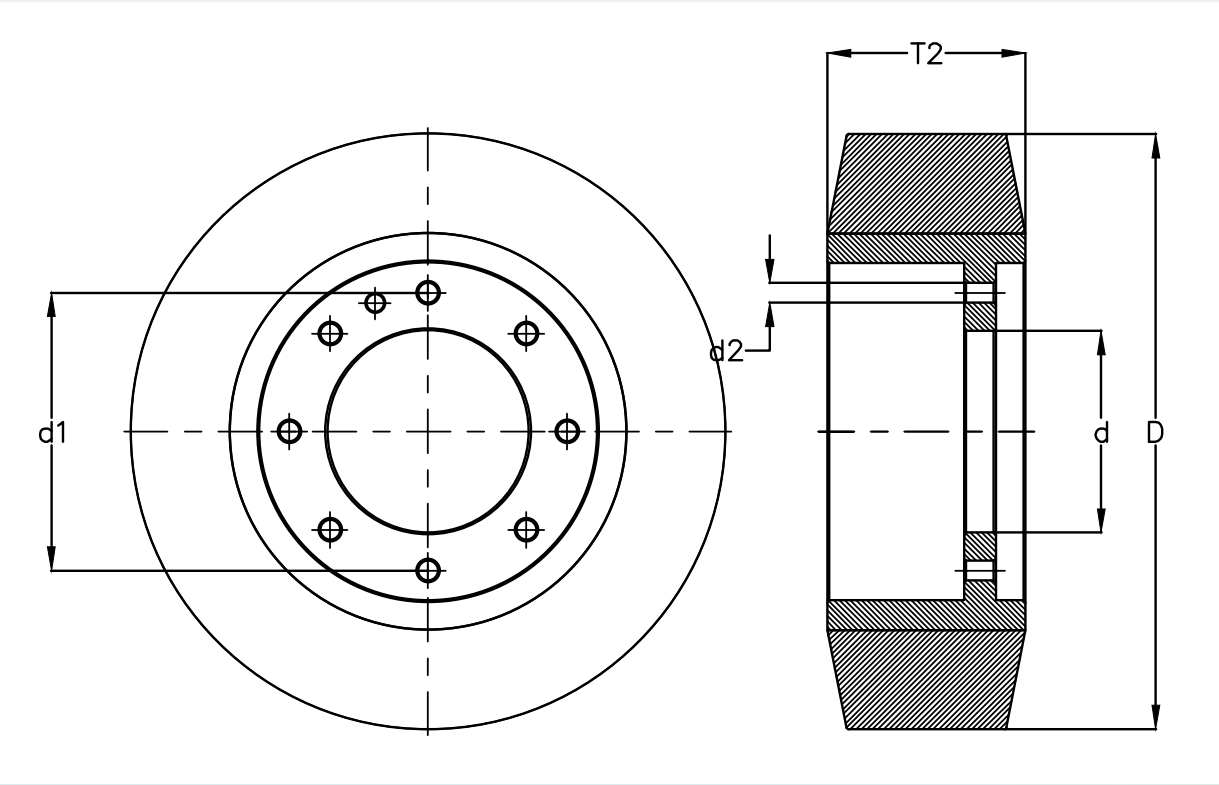

| Single wheel | Single Wheel Diameter (D) mm |

Single Wheel Width (T2) mm |

Load Capacity at 4KM (kg) |

Load Capacity at 10KM (kg) |

Load Capacity at 16KM (kg) |

Mounting Hole Diameter | Center Hole Diameter (d) [mm] |

PCD (d1) [mm] |

||||||||||

| GMFC 250/80 | 250 | 80 | 1800 | 900 | Customization Acceptable | |||||||||||||

| GMFC 250/100 | 250 | 100 | 2300 | 1150 | Customization Acceptable | |||||||||||||

| GMFC 300/80 | 300 | 80 | 2100 | 1050 | Customization Acceptable | |||||||||||||

| GMFC 300/100 | 300 | 100 | 2700 | 1350 | Customization Acceptable | |||||||||||||

| GMFC 360/80 | 360 | 80 | 2500 | 1250 | Customization Acceptable | |||||||||||||

| GMFC 360/120 | 360 | 120 | 3000 | 1500 | Customization Acceptable | |||||||||||||

| GMFC 400/100 | 400 | 100 | 3400 | 1700 | Customization Acceptable | |||||||||||||

| GMFC 400/125 | 400 | 125 | 4500 | 2250 | Customization Acceptable | |||||||||||||

| GMFC 415/125 | 415 | 125 | 5000 | 2500 | Customization Acceptable | |||||||||||||

| GMFC 500/150 | 500 | 150 | 6500 | 3250 | Customization Acceptable | |||||||||||||

| GMFC 500/200 | 500 | 200 | 8800 | 4400 | Customization Acceptable | |||||||||||||

| For other sizes, please contact us for inquiry | ||||||||||||||||||

The advantage of polyurethane lies in the fact that by adjusting the polyurethane formula, one can change its hardness, color, friction coefficient, etc., to achieve the effects of noise reduction, anti-static, and ground protection. Its long lifespan and low maintenance costs make it have a high overall cost-effectiveness. Various environments can be used, such as food-grade (without pollution), conductive-grade (for electronic workshops), and high-load (for port equipment).

We can customize the corresponding polyurethane wheels according to your requirements. Under normal circumstances, the maximum load can reach 10T and the maximum speed can reach 10 kilometers per hour.

Yes, we can adjust the polyurethane formula to meet different requirements.

The hardness range of polyurethane materials usually falls between Shore 70A and Shore 100D. High-hardness polyurethane materials have better load-bearing capacity and wear resistance, while low-hardness polyurethane materials offer better ground protection and noise reduction effects.

All the parameters can be customized according to your needs.

We support e.g., aluminum, steel, nylon cores

The minimum order quantity is 10 pieces. The delivery time is usually 25 days.

We support the proofing process, but we require you to pay the corresponding fees.

If delamination or cracking occurs within 24 months, we will provide a free replacement.