Have you ever asked yourself how a robot can travel without anyone controlling it? Well, actually, it’s all down to something called AGV wheel drive systems! AGV means Automated Guided Vehicle, and these awesome machines zip around doing work with the help of special wheels. How do AGV Wheel Drive Systems work?

AGV wheel drive systems are the feets of robot. In the same way you and I use our feet to walk, and run, AGVs use wheels to get from point A to point B. Electricity powers these wheels, which enable these machines to have the energy to roll smoothly enough to haul heavy loads. Isn't that cool?

Robots that do all the drudge work, so we humans can focus on other things. That’s the promise of AGV wheel drive technology! By implementing these sophisticated systems, organizations can automate their operations and increase their productivity in every way.

AGV robots using wheel drive technology can transport themselves around factories and warehouses and other industrial environments. They travel along pre-set paths and are even capable of avoiding obstacles. Humans, this saves a lot of time and effort, so you can do something creative or critical.

Logistics is the business of moving things quickly and cheaply from one place to another. Yep, the optimal to drive wheel AGV technology is ideal for this! These robots can move products around their warehouses, through their distribution centres, and even on the shop floor.

Warehouses are active spaces with many moving parts. AGV robots that can be powered by wheel drive tech can provide shop floor to close storage warehouse operations. They have the ability to grasp objects, shuttle them from one area to another and even help package them for shipping.

Time and cost saving with AGV wheel drive in warehouse. And they are fast, precise and consistent, which translates to greater productivity and fewer mistakes. And they can be on call 24/7, so that all of the work gets done when it needs to.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

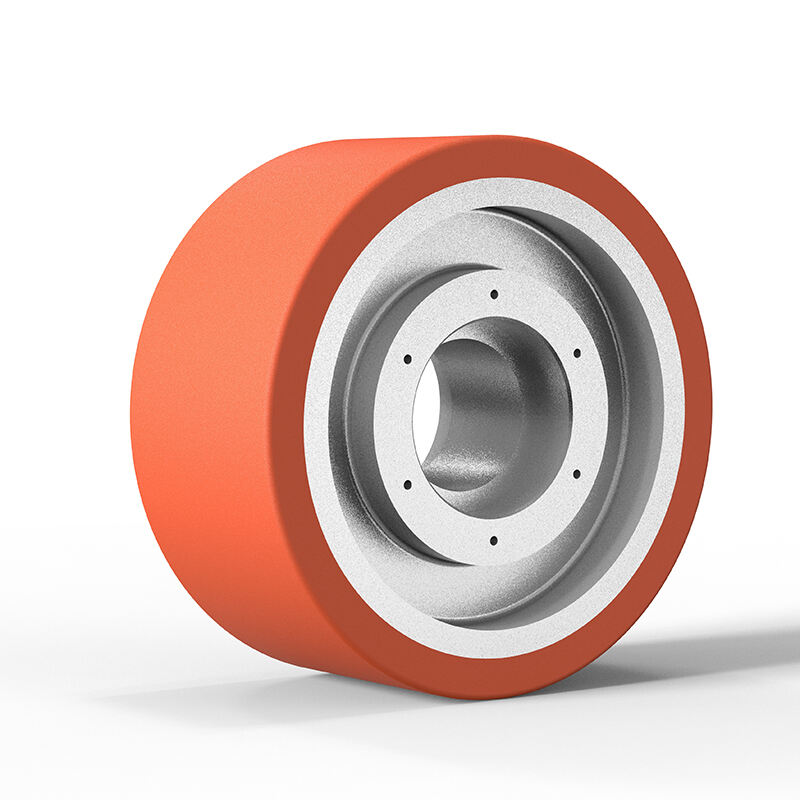

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.