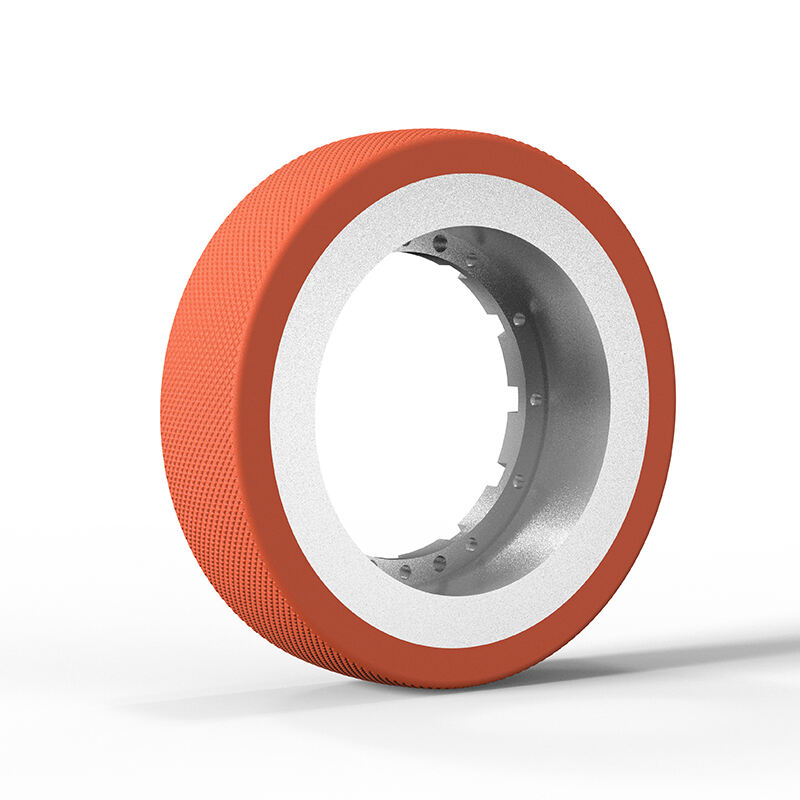

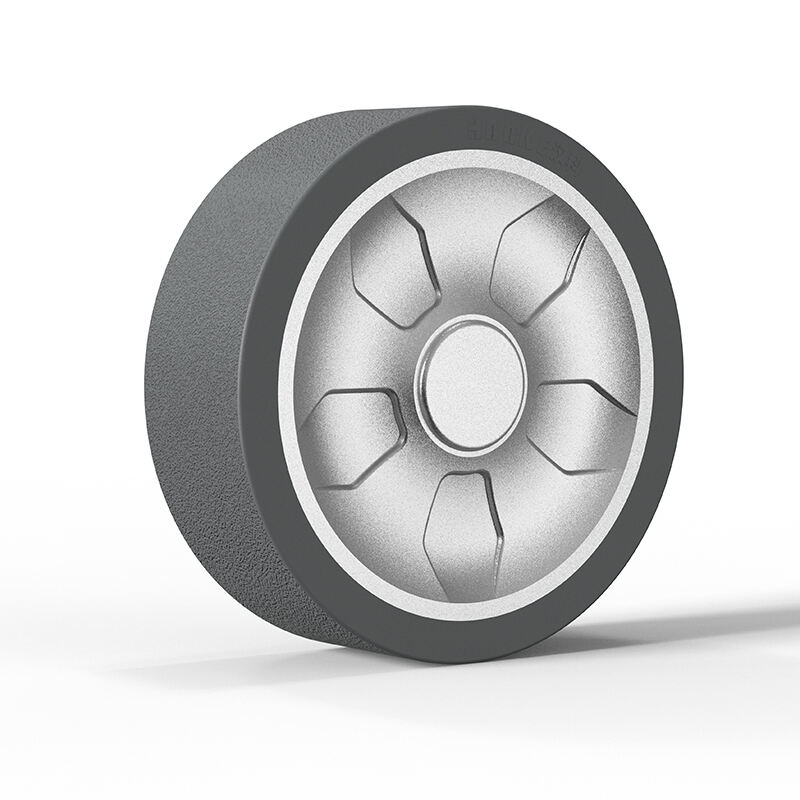

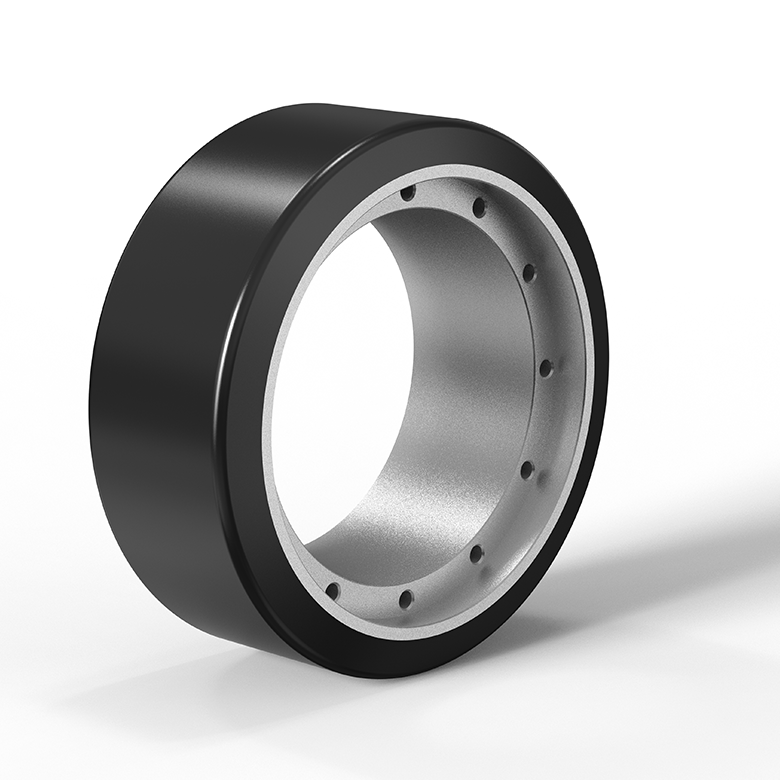

Polyurethane coated bearings are custom parts that keep machines working in a fluid motion. These bearings consist of a shield made of a strong polyurethane material. It does make them last longer and perform better than ordinary bearings. Hanke is a manufacturer that produces highly durable Polyurethane drive wheel & polyurethane coated bearings that are found in industries in many types of machines.

How Polyurethane Coated Bearings Are Better Than Traditional: Traditional bearings are metal - which easily rusts and is worn over time. When it occurs, the machine that they are in does not function so well. The metal bearings need to be replaced more often as they rust and wear out, which is not the case with the polyurethane coated bearings. This makes them a better fit for machines that have to run all the time.

Benefits of Polyurethane Coated Bearings: There are several advantages to using Polyurethane guide wheel & polyurethane coated bearings. First and foremost, these types of bearing systems can work in a variety of environments. They also can withstand temperature and abuse extremes without breaking. This makes them highly adaptable and suitable to different type of machines. A further benefit is that they facilitate noise and vibration in machines, leading to quieter and smoother operation.

The Application of Polyurethane Coated Bearings in Machinery: The application of polyurethane coated bearings is very extensive. They make different parts of a machine go together and move together easily — so that they don’t get stuck. This is necessary for machines to function correctly and to adopt near optimal policies in a timely manner. If it was not for good bearings, machines would not function properly and would wear out quickly.

Shit You May Not Know About Polyurethane Coated Bearings Investing in Polyurethane bearing are a smart investment for businesses that operate machinery. Such bearings can make machines run better and last longer, potentially saving money in more ways than one. They also reduced the chance of breakdowns and repairs, which can be expensive. On the whole, selecting a polyurethane coated bearing makes sense for any business that needs its machines to work well and last a long time.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.