“PU rubber rollers are the original most helpful tools to help make things better in factories and any other places big machines are used.” Now, what are the features of these rollers made with a special material known as polyurethane, which is very strong and is tough? PU Rubber Rollers In this article, we are going to read about PU rollers and how they can simply things for you and make things work quickly for you.

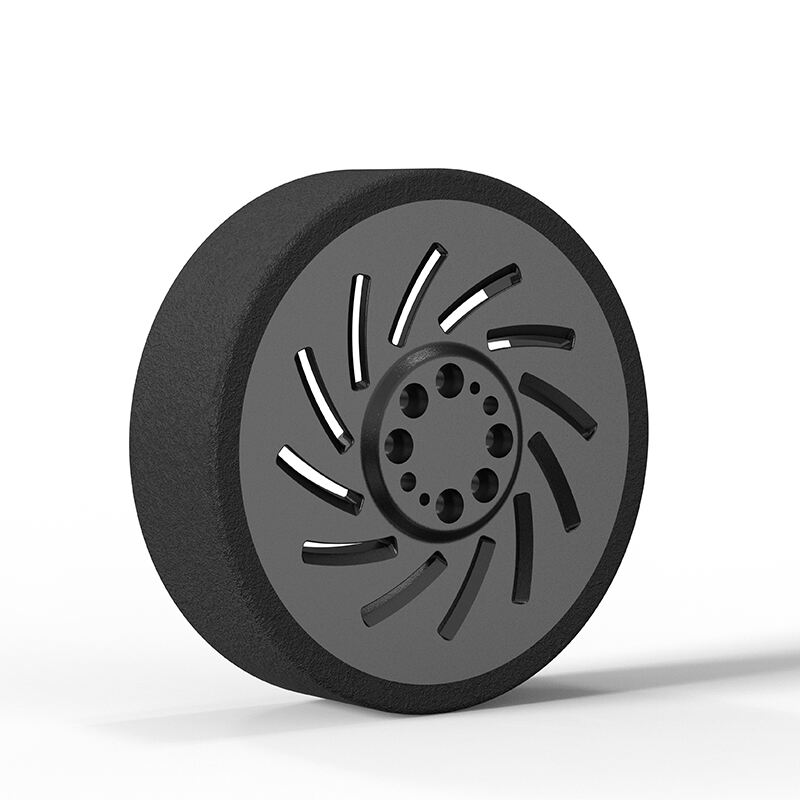

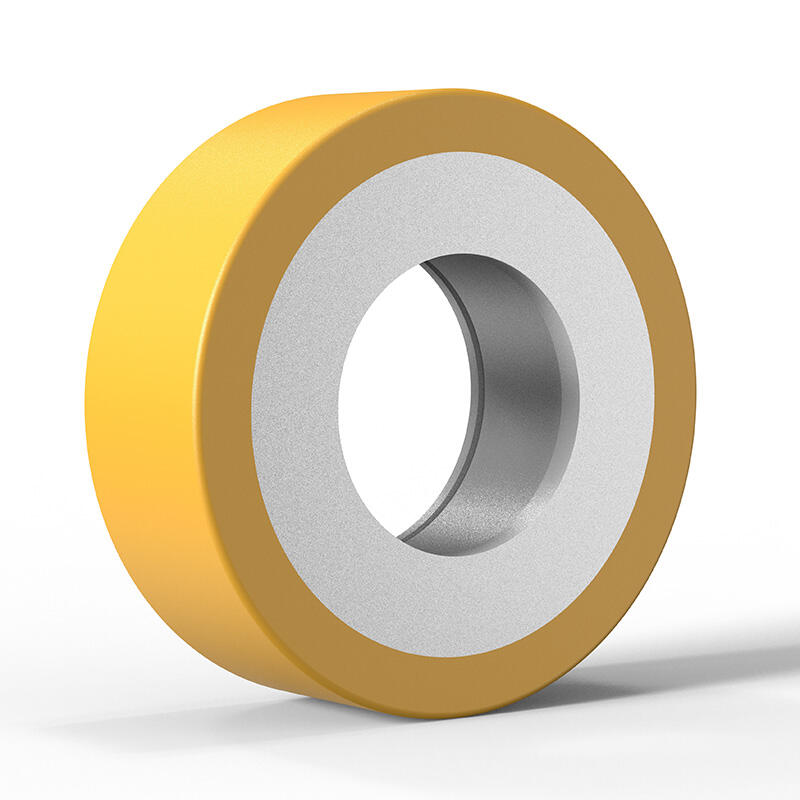

PU rubber rollers are in a way a Goliath in the industrial space. They can be very versatile and keep things moving. The reason PU rollers are so popular is that they are absolutely brilliant at gripping things and moving them. This makes them a good match for processes like printing and coating, in which one has to move things just so, very carefully, to ensure that the final product ends up looking good.

For printing, coating, precision is everything. It is here where PU rubber rollers apply. So these are little helpers that make it so line like it’s the ink Is spread across and even out runners if you do run it there. This is the key to the high quality of products that can be beautiful. PU rubber rollers also excel in shock and vibration absorption, which can reduce mistakes and errors during the printing and coating processes.

PU rubber wheels are tough and durable. They can take a beating — without losing their shape or stickiness. This makes them great for being used in machines in which they are in constant motion and under heavy loads. PU rubber roller has long lifespan that will help save maintenance costs as they do not need to be replaced as frequently.

PU rubber wheels are the all rounders of industrial. They serve nearly every industry in the world, from feeding chemicals to sensitive, precise feeders up to transporting rock at 30 ton +. PU rubber rollers have great gripping properties and are ideal for safely transporting material from one area to another. They are also adjustable for different sizes and shapes, thus are flexible and suitable for various purposes.

Just like any superhero, PU rubber rollers have their weaknesses and sometimes they can face some problems. A shortcoming of PU rubber rollers is that they may become damaged or dirty, which compromises its performance. To resolve this, you need to ensure the rollers are clean and checked at frequent intervals for wear. If a roller is damaged, repair or replacement may be needed in order to maintain the equipment's peak performance.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.