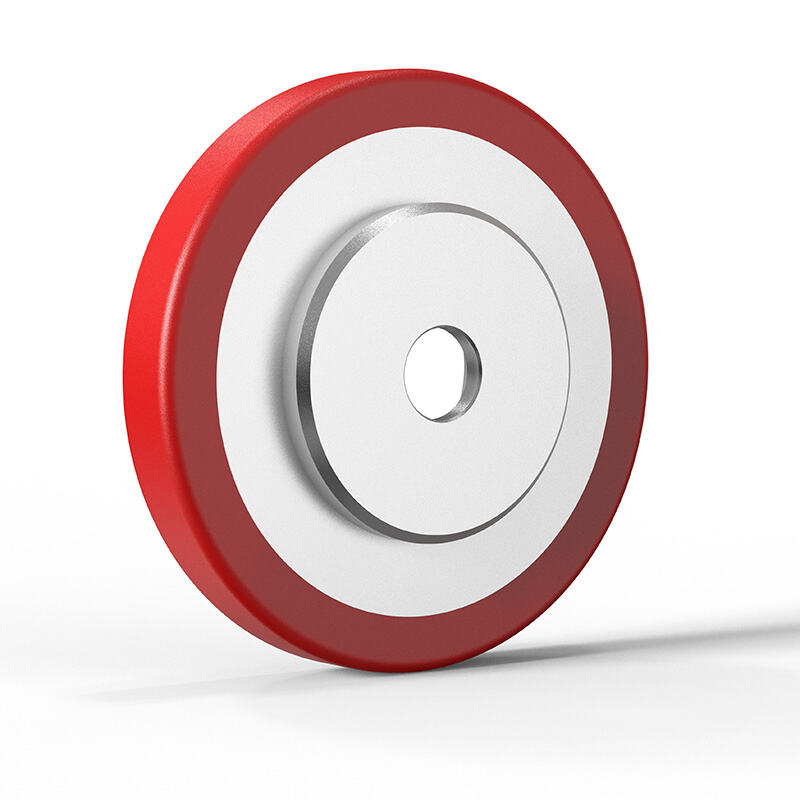

When selecting wheels for various machines and equipment, a few choices are available. There are two commonly used types of wheels including polyurethane wheels and roller wheels. But what is the difference between the two, and which is the best option for you? Below, we’ll take a closer look at polyurethane wheels, and roller wheels to help you choose the right wheel for your business polyurethane flanged wheels

Polyurethane wheels are long lasting and resistant to wear. They are constructed from a hardwearing material and are strong enough to carry heavy loads over rough ground. Roller wheels, on the other hand, are made out of a hard material and this may break down faster, especially when used on hard surfaces. This also means that polyurethane wheels are the longer lasting and more cost effective replacement.

Polyurethane wheels have a lot going for them when compared to foam roller wheels. In any case, one of the benefits is the fact that polyurethane wheels offer better traction. That is, machines with polyurethane wheels can better grip the ground and are ultimately sturdier and less prone to slipping or skidding. On the other hand, polyurethane wheels are also quieter, rolling smoother down the road, a more pleasant experience for operator and bystander alike.

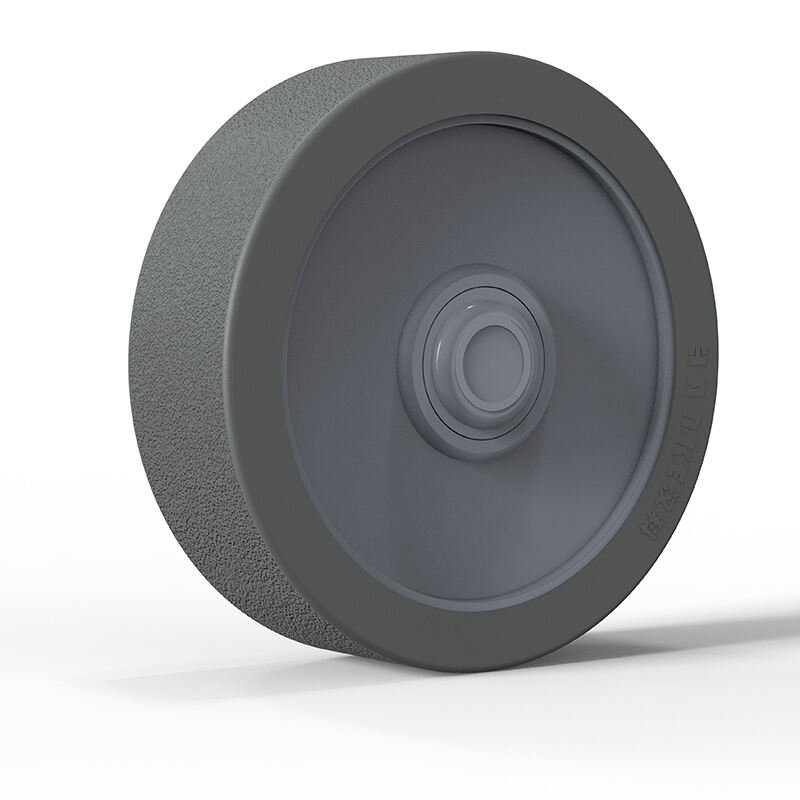

Polyurethane Wheels and Roller Wheels: It is important to note that polyurethane wheels and roller wheels have different performance features making them useful for different jobs. Polyurethane wheels are less rigid and have a higher load capacity that is suitable for heavy duty applications. Roller wheels are intended for light-duty applications where the wheel rolls smoothly and easily due to the beaded rim style offer as opposed to the load capacity. Knowing these differences allows you to select the desired kind wheel for your specific application.

When making a choice between polyurethane wheels and roller wheels, you'll also want to consider what your application is and the environment that these wheels will work in. If you require wheels with a heavy load capacity or ruggedness, polyurethane wheels are the best option. If instead you need wheels for light use which you can roll quietly, roller wheels might be the right wheels for you. It is possible to work out what you need and also what are your options in terms of wheel performance for these two types of wheels.

Polyurethane wheels' versatility makes them ideal in the many applications. Whether it is an industrial piece of equipment or the appliance found in your home, rubber wheels can offer the strength and dependability required for numerous applications. Another plus to the polyurethane wheels on the chairs is that they can be used for a very long time without having to replace them as well as not costing as must as ones that are simply made of plastics. If you are in a need of wheels for a forklift, hand truck or conveyor belt, polyurethane wheels is a flexible choice for you, can fit your needs.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.