4Ply Polyurethane drive wheels are wheely great! At Hanke we know how Polyurethane drive wheel can work better and last longer than ever before. In this post, we will discuss the benefits of these special wheels and why they are suitable for a wide range of industries.

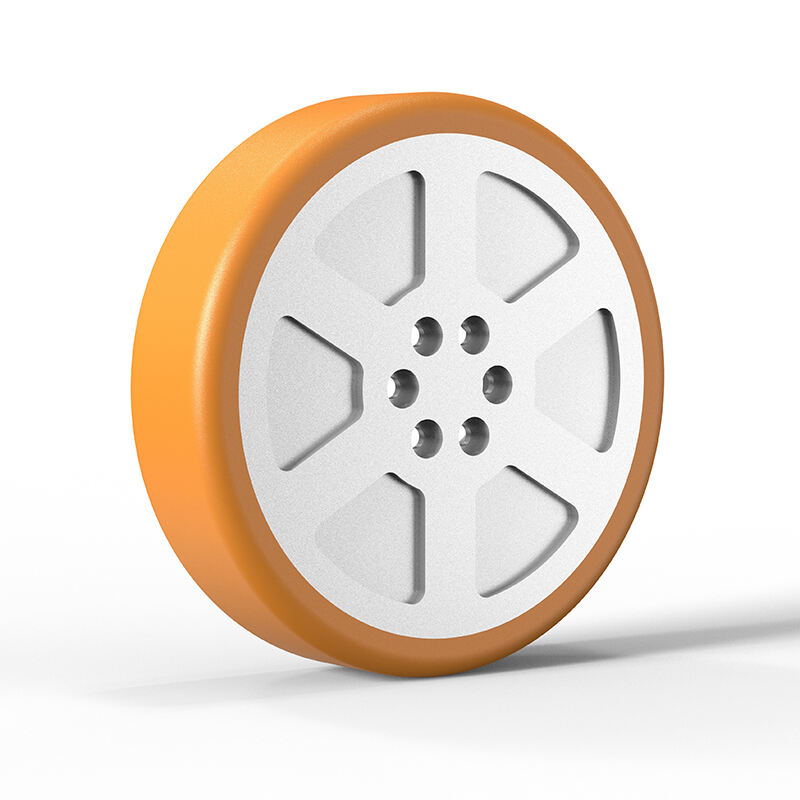

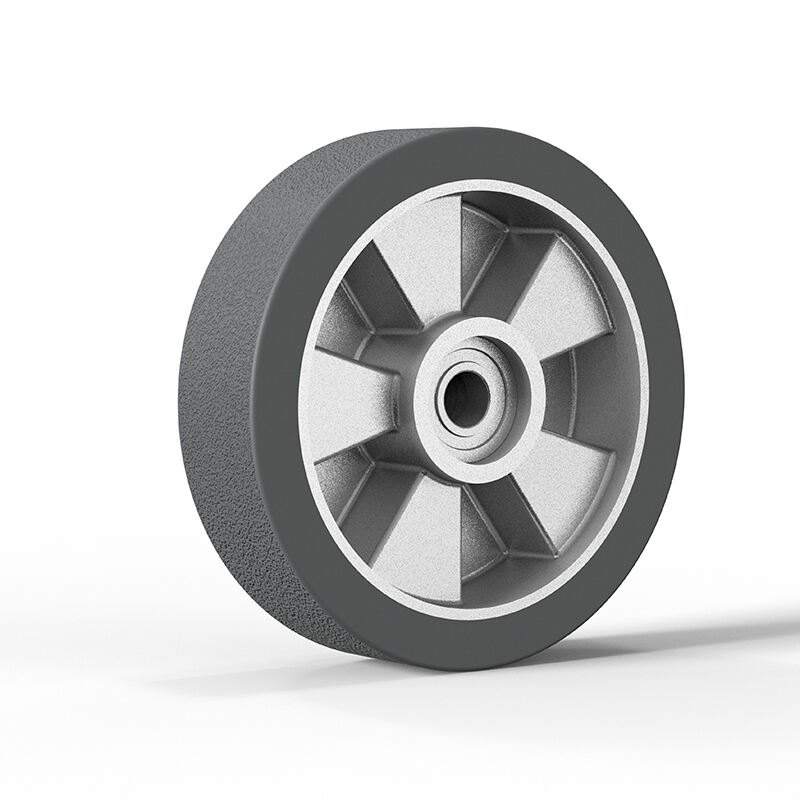

What Are Polyurethane Drive Wheels? Polyurethane drive wheels are no more than wheels constructed out of a special sort of plastic: polyurethane. These wheels are extremely tough, to so they can be used under large loads and on rough surfaces without wearing out. That makes them ideal for all kinds of machines that move around a lot, such as forklifts and conveyor belts.

Polyurethane drive wheels are a great option because they can take a lot of wear before breaking down. This is why machines with polyurethane drive wheels can continue to run smoothly for years without the expense and downtime of costly repairs or replacements. With polyurethane drive wheels, you can rely on your equipment to power through.

Advantages of polyurethane drive wheels include:Traction – Polyurethane Idler wheel offer better traction and grip than alternative models, resulting in improved efficiency in the machinery. This makes it easier for machines to twist and turn, potentially saving time and energy. This means that when compared with conventional drive wheels, which are often made of metal or another hard material, polyurethane drive wheels can allow machinery to work faster and are more efficient, which means businesses can get more done in less time.

Polyurethane drive wheels are a wise investment for many businesses and can save money over the long run. And since these wheels are so rugged, they can live over a long time, longer than some other type of wheels. This has implications for business as well, as companies will have to expend less money replacing worn-out or repairing broken wheels. Selecting polyurethane drive wheels can ensure organizations save time and money over time, keeping operations running seamlessly for many years to come.

The use of polyurethane drive wheels can be useful in a variety of industries. Warehouses and distribution centers, for instance, employ forklifts with elliptical drive wheels made from polyurethane to move heavy loads in and about their facilities in a safe, efficient manner. Production facilities utilize conveyor systems that are powered through a system of polyurethane drive wheels for the transportation of products from end-of-line to end-of-line. Airports even employ luggage carts with Polyurethane guide wheel & polyurethane drive wheels to ensure passengers can get their bags to the right place in time.

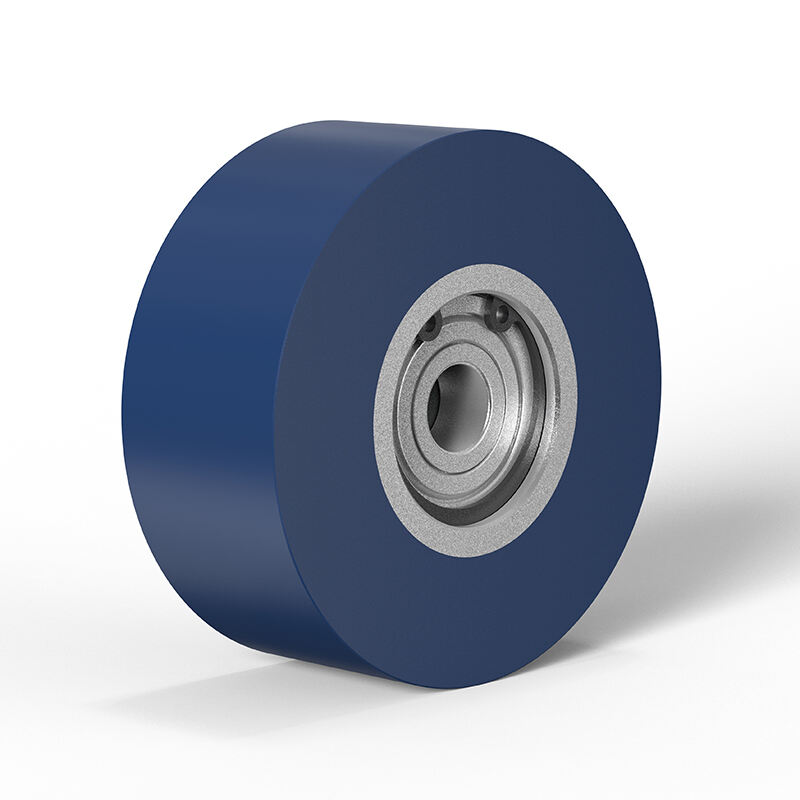

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.