Idler pulley wheels are one such important part of your machine drive wheels at enable it to work efficiently. It’s like a little helper that keeps things running seamlessly. Here’s a little more information about how they work and how to care for them

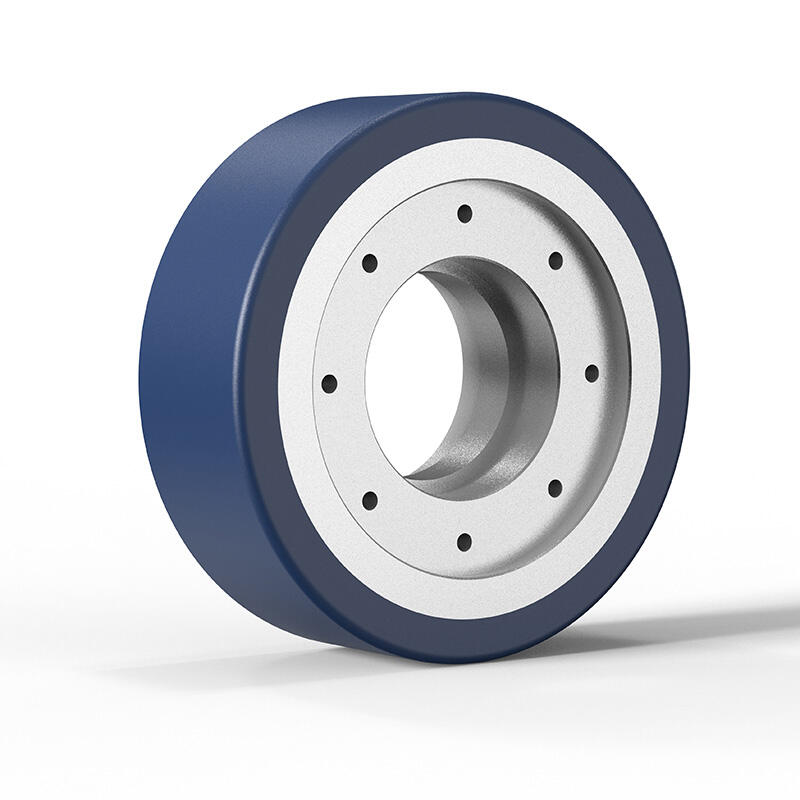

An idler pulley wheel, for example, is a little wheel that doesn’t move by itself. It assists in turning other wheels by a belt or chain running along its circumference. This makes life easier for the machine. Things wouldn’t quite work as well without the idler pulley wheel.

When selecting an idler pulley wheel for your machine, consider the belt size and material as well. Various machines require various idler pulley wheels to function great. If you need assistance you can ask another adult or a mechanic to help you find the best one for your machine.

Like anything else, idler pulley wheels require maintenance. You should monitor them early and often to ensure they function as they should. If you observe anything such as squeaking or wobbling, your idler pulley wheel may need to be replaced. This will make your machine work more effectively and last longer.

It so the idler pulley wheel is popping in the appropriate place to work well. If it isn’t timed correctly, issues like the belt or chain slipping can occur. You can use tools to line them up and keep everything where it belongs.

Some times they can be with issues with the idler pulley wheels, but in fact, you don’t need to worry at all, because almost all of that is solved, well. Should you hear sounds, vibrations, or have an issue with the belt or chain, you can also consider cleaning and/or lubricating the idler pulley wheel. If all else fails, it might be time to replace it with a new one.

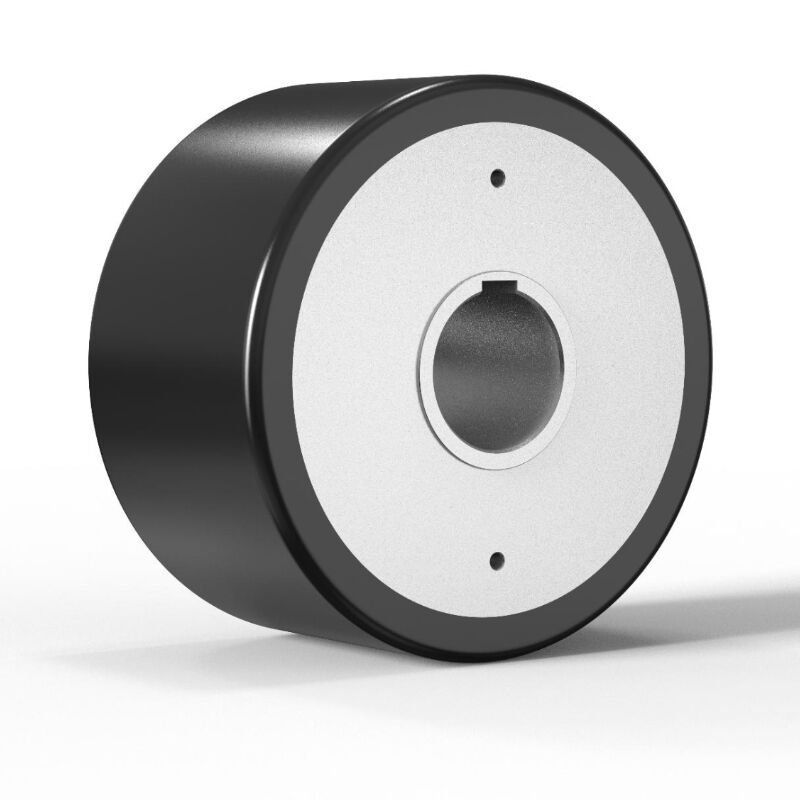

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.

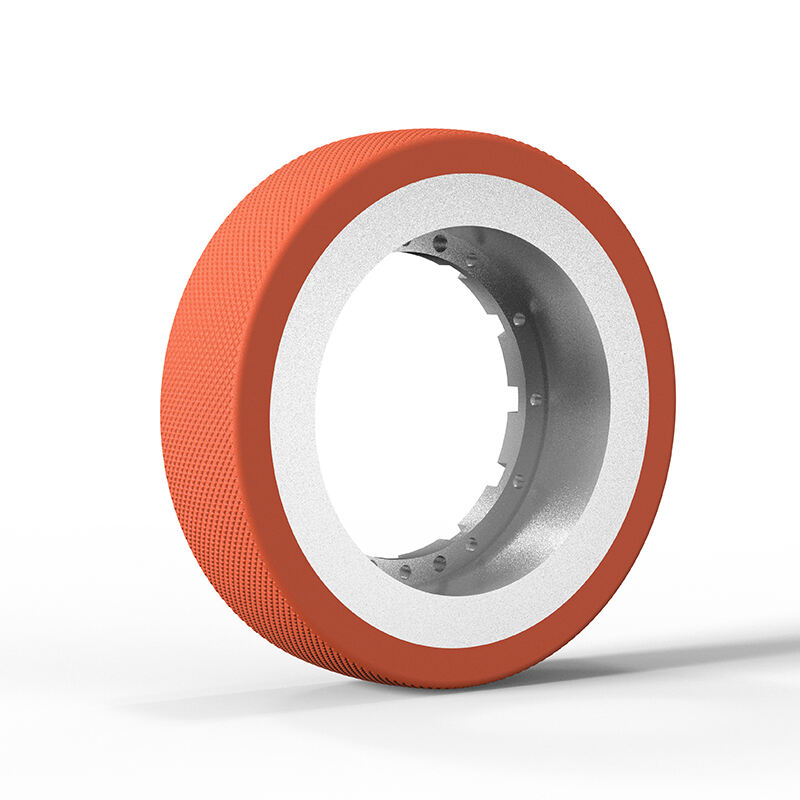

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.