Guide wheels are a critical component to some of the machines and equipment used in factories and warehouses. They're there so things go smoothly and safely, the same way the wheels on a bicycle keep you from tipping over. By the way, we will discuss the significance of Hanke linear guide wheels for industrial machinery, and its roles for accuracy and stability in automation.

Guide wheels are an indispensable part of machinery in industrial production. They do make it easier to stay on course and point in the right direction. Machines without guide wheels can wobble or drift, leading to accidents or inaccuracy in production.

Even in systems that are automated, guide wheels are comparable to what you will find in a steering wheel during driving a car. They’re used to manage the flow of materials or products along a conveyor belt or assembly line. With some guide wheels, engineers can maintain order, keeping everything aligned and moving where it needs to.

Efficiency is important in material handling systems. Guide wheels assist in promoting the flow of materials by minimizing the chances of jams or blockages. Hanke elevator guide wheels pay off to steer objects where they need to go, reduce friction and move at high speeds, which maximizes productivity and minimizes downtime.

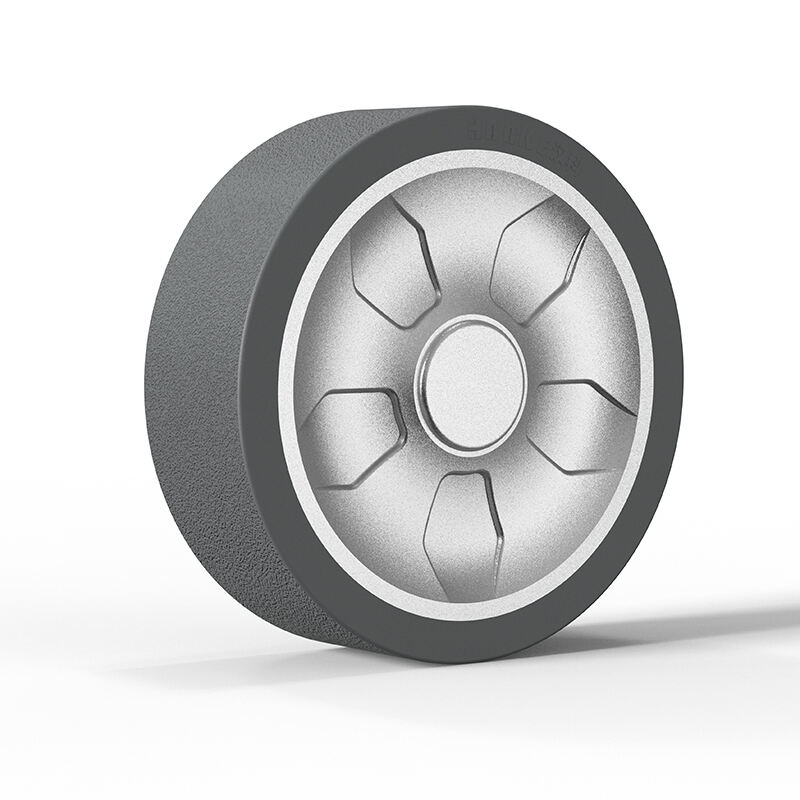

Guide Wheels Need to Knows When picking guide wheels for your machinery, it’s critical that you pick the right ones for the job. A variety of materials and sizes of guide wheels are also available and can be used in specific applications. The Hanke small guide wheels offers a selection of guide wheels that are rugged and dependable that stand up to long hard use.

Guide wheels are extremely versatile and can be used in a multitude of applications. From the robots we use today to packaging machines, guide wheels are a vital part to keeping things traveling straight and true. No matter which industry you are, food or automotive, Hanke spring loaded guide wheels are necessary for good working.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.