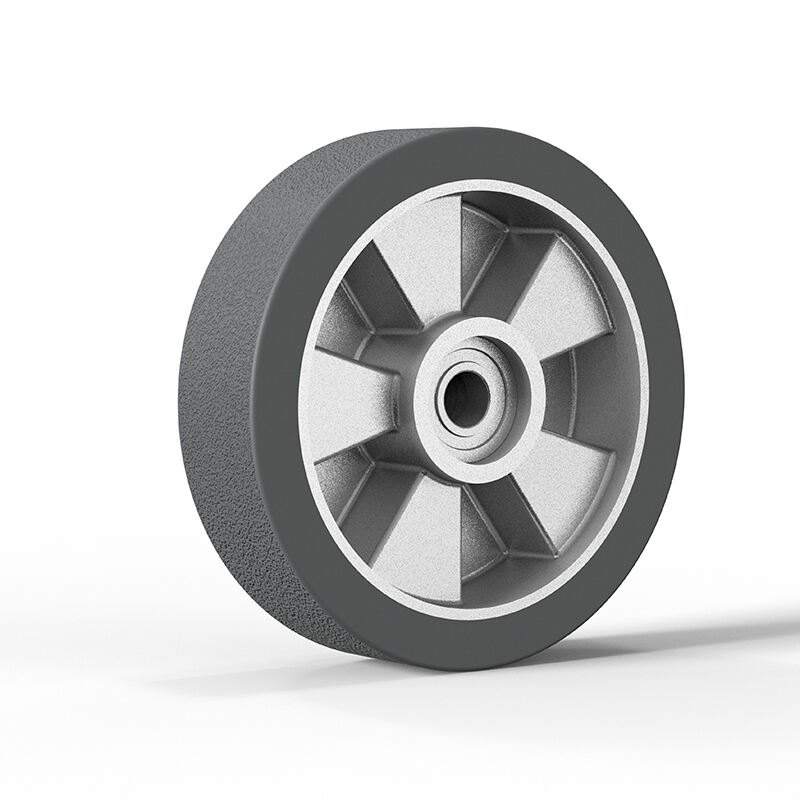

Hanke Conveyor rollers and pu bearing are a very important portion of most production lines. PU Conveyor Roller A popular kind of conveyor roller is the PU conveyor roller. PU stands for polyurethane, a material that is durable and long-lasting. In this post, we will discuss the advantages of using a PU conveyor roller in your production line, how it helps to increase the productivity of your operations, its long life expectancy and durability, the reasons why it is a top pick for a lot of industries, and how to identify the best PU conveyor roller for your application.

Benefits of PU conveyor rollers have multiple benefits, making them the perfect addition to your production line. One of the greatest advantages is that PU has good resistance to wear, so the rollers will be long lived and will take a lot of hard use. This can save you money over time as you'll need to replace your mats less often.

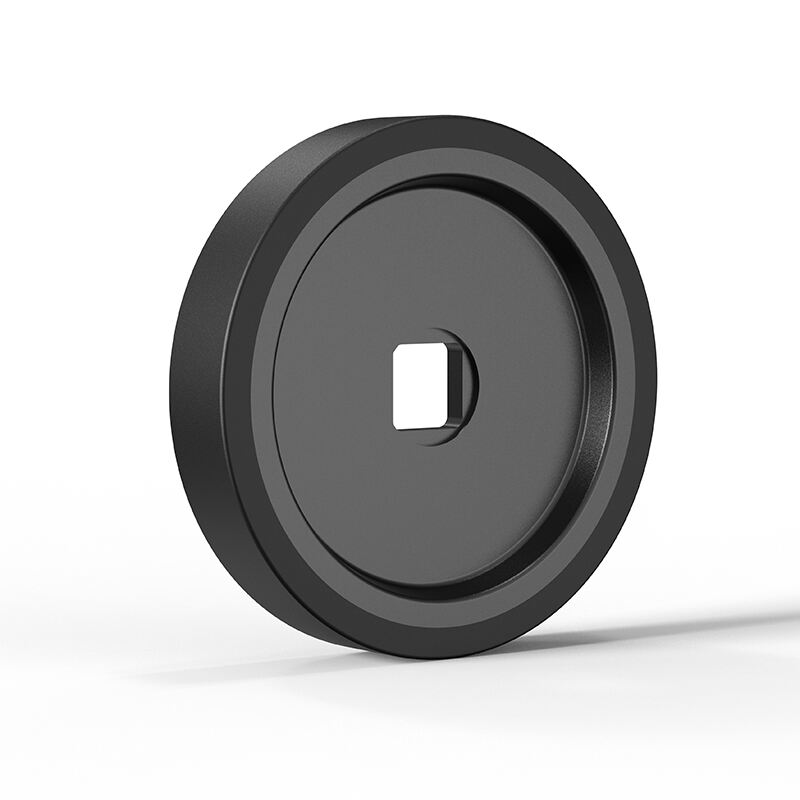

The merits of adding Hanke PU conveyor rollers and pu castor wheel to your production line You are well your way to perfect production with the PU conveyor rollers. With no sharp contrast, good performance in rolling goods in and out of the table, the rollers can transmit the goods from one place to another on the belt conveyor, no damaging goods for the tapered rollers, and the goods will be pushed to move forward, so it can reduce the friction and promote the goods transport, the goods can be easily and quickly moved on the belt. This can improve the speed of your production line and minimize the likelihood of jam or backup.

PU conveyor rollers, as well as being functional, also prove to be a very cost-effective solution. They are used in many applications, from food and beverage processing to automotive and aerospace, where effective sealing is required. PU’s chemical, oil, and abrasion resistance stands behind the quality of this material, and the PU material in general also makes it an ideal choice for environments where severe duty is achieved.

Other Hanke PU conveyor rollers and heavy duty pu wheels are widely used in food processing and packaging industries for mass production, the smooth surface allows them to be used where hygiene is paramount like the pharmaceutical and electronics industries. PU rollers are easy to clean and maintain- so your products will be protected from contamination while they're in production.

There are a variety of factors to consider when selecting a PU conveyor roller and agv wheels for your application. First of all, you need to consider the size and weight of the items you are going to be relocating, as this will have an impact on the size and load/carrying volume of rollers that you will require.

The environment in which the rollers and agv drive wheel will be used should also be taken into account as well. Should you be working in wet or oily conditions, you might require rollers that resist moisture and chemicals. If you happen to be working in a clean environment or in a food factory you may need rollers that you can clean and maintain with ease.

With roots dating back to 1989, our founder led the development of China's first polyurethane elastomer casting machine, giving us over three decades of deep technical expertise in polyurethane molding solutions.

Guided by a simple commitment to quality and affordability, we aim to build lasting, win-win relationships, helping customers achieve sustainable growth through reliable products and shared success.

We utilize advanced equipment, high-quality raw materials, and sophisticated production technology, supported by a rigorous management system to ensure efficient, high-standard manufacturing of polyurethane wheels.

Established in 2019 specifically for polyurethane wheels, Hanke focuses on closing the quality gap with imported brands, delivering high-performance rollers at competitive prices to enhance customers' market competitiveness.