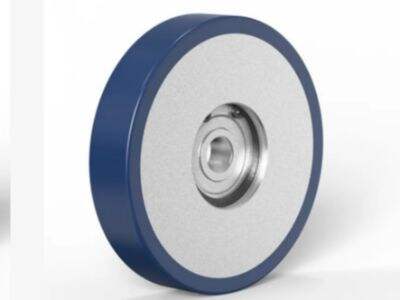

Investigating the influence of bearings on high‐speed polyurethane guide wheels

It is the bearing that determines the overall performance of high speed polyurethane guide wheel. These little power-houses allow the guide wheel to rotate free of drag and friction. Without a good quality bearings, guide pulley can not work in the best condition, it may wear rapidly, effecting the efficiency of frequency, and even damage. So choosing the right bearing of Polyurethane guide wheel are very important to keep the good performance in high speed.

Quickly contrasting advantages of various bearing choices for polyurethane guide wheels

There are a number of various bearing options to consider when selecting bearings for polyurethane guide wheels. Ball bearings are popular because they are frictionless and robust. Roller bearing construction provides higher load capacity and better shock resistance. Ceramic bearings are also popular because of the extended service life, lightweight and corrosion resistance features. The benefits of each of these bearing types are compared so that machine builders can make an informed selection regarding the best bearing for their particular guide wheel application.

Choosing the proper slide way bearings for high speed guide wheels

To choose the appropriate bearing for high-speed polyurethane guide wheels, you must consider several factors. The speed, load, and environment of the guide wheel must be evaluated. In addition, the cost, maintenance and life from bearings should also be considered by designers. Choosing the correct bearings which are specifically designed for the application will contribute to the Hanke wheel guide performance and lifespan in high-speed environments.

How would they know the significance of Precision Ball Bearings for maximizing the efficiency of Polyurethane Guide Wheels

With high-speed use in particular, precision bearings are an important factor in preventing guide wheel polyurethane from ‘spinning out’ due to excessive friction. These bearings are machined to higher standards for consistent friction-free running. Smother running, lower noise, high efficiency Guiding wheel precision bearings used-Smooth running, low noise and high efficiency Machnes are easy to adjust, operate and maintain. Machined to close tolerances and designed for perfect fit and rotation, this bearing upgrade boosts the performance of high speed, polyurethane guide wheels.

CMS Applied Technologies Bearings Guide to the labyrinth of bearing options available for high speed urethane guide wheels

It can be a little daunting for manufacturers to navigate the intricate world of the high-speed polyurethane guide wheels bearing options available. With so many seats to choose from, and such varied pros and cons, it’s critical to pinpoint the specific needs of your situation.

Table of Contents

- Investigating the influence of bearings on high‐speed polyurethane guide wheels

- Quickly contrasting advantages of various bearing choices for polyurethane guide wheels

- Choosing the proper slide way bearings for high speed guide wheels

- How would they know the significance of Precision Ball Bearings for maximizing the efficiency of Polyurethane Guide Wheels

- CMS Applied Technologies Bearings Guide to the labyrinth of bearing options available for high speed urethane guide wheels