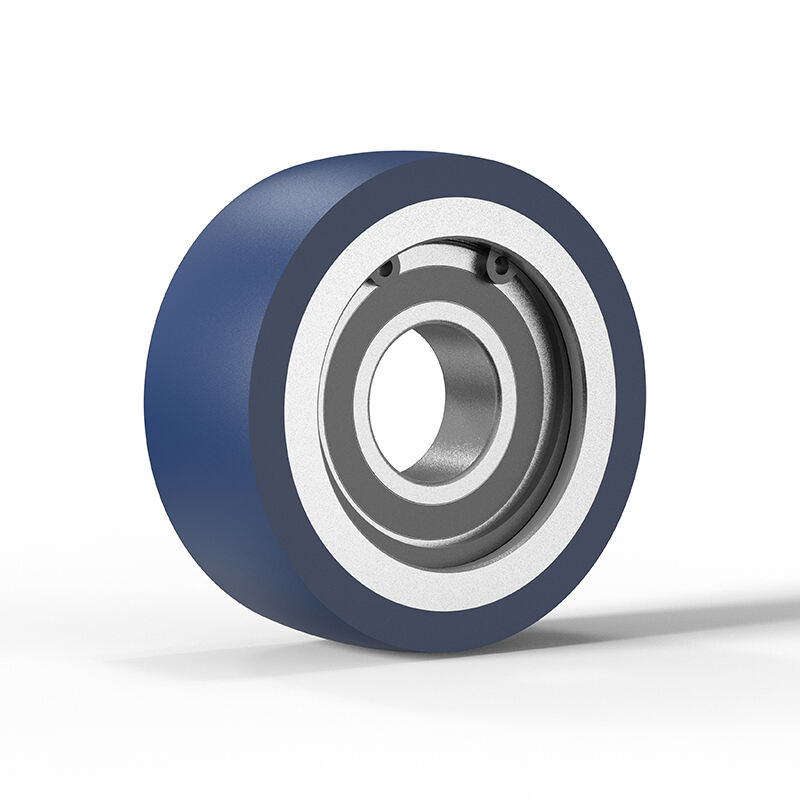

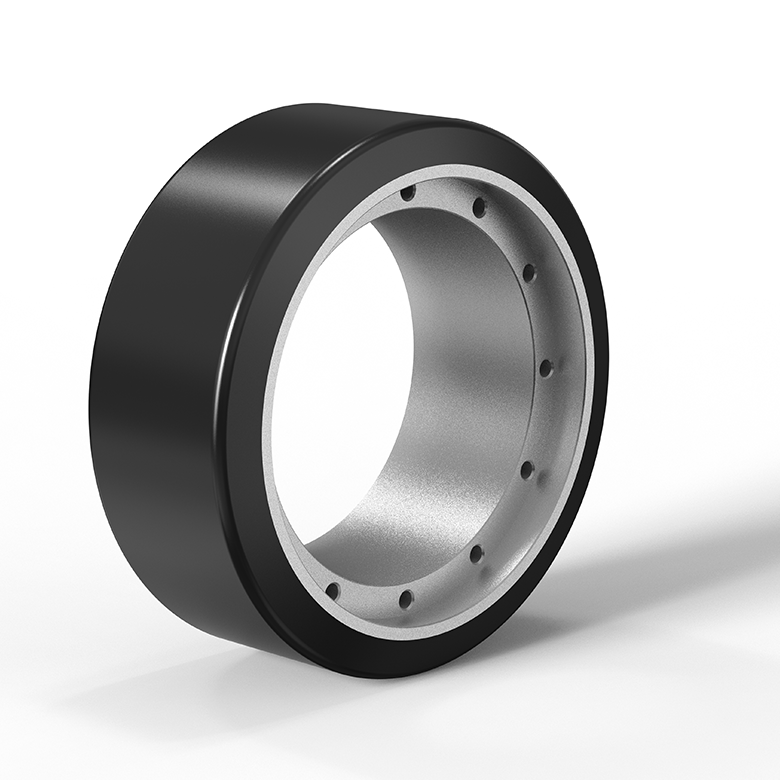

Los rodillos de accionamiento de poliuretano son ruedas especiales que se utilizan para empujar cosas de un lugar a otro en fábricas (y en otros lugares, por cierto). Estos rodillos, fabricados con un material resistente llamado poliuretano, permanecerán operativos durante mucho tiempo y funcionarán muy bien. ¡Y ahora conozcamos estos geniales productos de Hanke!

Los Rodillos de Poliuretano Se utilizan en fábricas y otros entornos industriales, existen muchos beneficios al usar poliuretano y rodillos de uretano para impulsar. Una ventaja importante es que son extremadamente duraderos y pueden soportar objetos pesados sin sufrir daños. Esto los ha hecho capaces de durar mucho tiempo y por esta razón no necesitan ser reemplazados con frecuencia. Otra ventaja excelente de los rodillos de poliuretano es que tienen un agarre excelente, lo cual ayuda a mover las cosas de manera eficiente y sin problemas. Esto puede hacer que el trabajo en las fábricas sea considerablemente más rápido y sencillo, causando un tiempo de respuesta más rápido.

Los sistemas de transporte son máquinas que ayudan al movimiento de algo de un lugar a otro, por ejemplo, una línea de ensamblaje. Estos pueden ayudar a que los sistemas funcionen más eficaz y efectivamente si utilizan rodillos de accionamiento de poliuretano. Debido a la composición del material, rodillos de poliuretano personalizados son fuertes y duraderos y pueden funcionar durante mucho tiempo sin complicaciones, de modo que el sistema de transporte opere continuamente sin interrupciones. Puede ayudar a que las fábricas produzcan más productos en un periodo más corto de tiempo, haciéndolas más eficientes y productivas.

Los rodillos de accionamiento de poliuretano también tendrán mayor resistencia al desgaste que otros materiales. Mientras algunos tipos de rodillos pueden dañarse fácilmente o desgastarse rápidamente, los rodillos de poliuretano Hanke pueden durar mucho tiempo. Eso significa que no necesitan ser reemplazados con tanta frecuencia, ahorrando tiempo y dinero a las fábricas. Por qué rodillos de poliuretano para bandas transportadoras son la Solución Con rodillos de accionamiento de poliuretano en funcionamiento, las fábricas saben que pueden confiar en ellos para seguir trabajando día a día sin preocupaciones.

Los costos de gestión pueden aumentar rápidamente en fábricas que deben continuar reparando o reemplazando piezas de sus máquinas. Las fábricas pueden reducir estos costos porque los rodillos de transmisión de poliuretano son muy resistentes y duraderos. Esto ofrece un doble beneficio: significa que es menos probable que se rompan o que necesiten ser reemplazados, lo cual ayuda a ahorrar dinero en mantenimiento. Dado que están equipados con Rueda motriz de poliuretano rodillos, las plantas pueden confiar en que continuarán funcionando sin requerir un servicio constante que implique reparaciones interminables en la línea, reduciendo así el costo total de mantenimiento de las unidades.

Rodillos de accionamiento de poliuretano, tienen una amplia variedad de usos en una serie de industrias diferentes. Ideales para fábricas que producen automóviles, ropa o incluso alimentos, ya que pueden levantar cargas pesadas y mover artículos fácilmente. Los rodillos de accionamiento de poliuretano también se utilizan en espacios como almacenes o centros de distribución, para impulsar cajas y paquetes a gran velocidad. Los rodillos de accionamiento de poliuretano de Hanke disfrutan de una amplia y flexible aplicabilidad y pueden emplearse en todos los proyectos en los que el trabajo humano sea arduo e ineficiente.

Guiados por un compromiso sencillo con la calidad y la asequibilidad, buscamos establecer relaciones duraderas y mutuamente beneficiosas, ayudando a los clientes a lograr un crecimiento sostenible mediante productos confiables y el éxito compartido.

Fundada en 2019 específicamente para ruedas de poliuretano, Hanke se centra en reducir la brecha de calidad con las marcas importadas, ofreciendo rodillos de alto rendimiento a precios competitivos para mejorar la competitividad de sus clientes en el mercado.

Con raíces que se remontan a 1989, nuestro fundador lideró el desarrollo de la primera máquina de colada de elastómero de poliuretano en China, lo que nos brinda más de tres décadas de experiencia técnica profunda en soluciones de moldeo de poliuretano.

Utilizamos equipos avanzados, materias primas de alta calidad y tecnología de producción sofisticada, respaldados por un sistema riguroso de gestión para garantizar una fabricación eficiente y de altos estándares de ruedas de poliuretano.