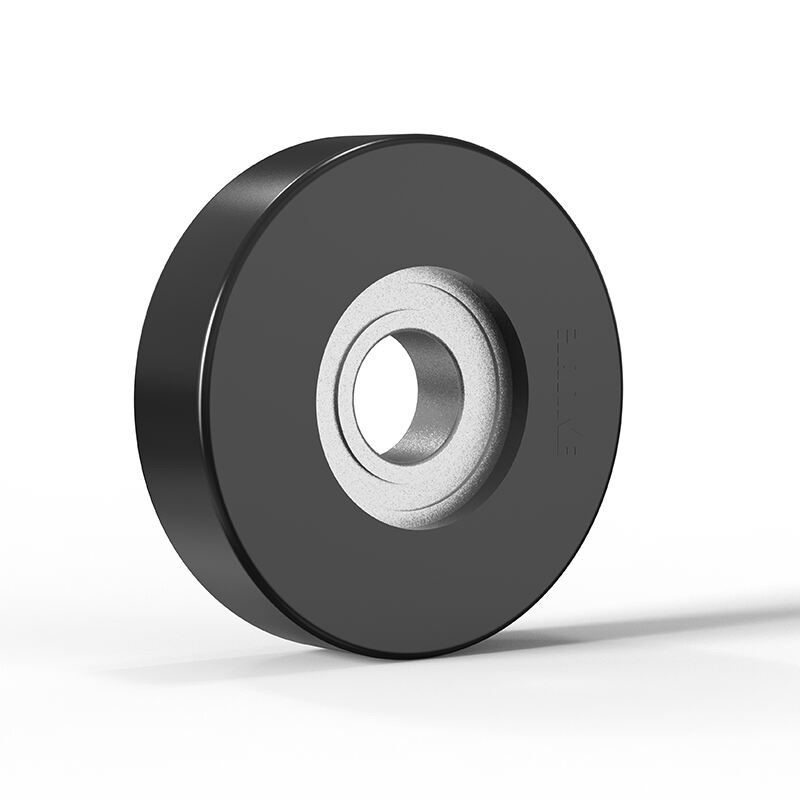

Selecting the proper bearing fit for lemon-driven wheels when selecting the right bearing fit for polyurethane-driven Wheels, it is important to know how bearings function and where they go in your wheel design. Hanke is committed to providing you with excellent service, by importing the best bearings to ensure our wheels run well and last. The proper fit makes the wheel turn smoothly and minimizes wear. Choose the wrong bearing, and you could have a wheel that just does not perform. This may make your machines slower and could be damaging. In the industrial world, where every piece counts and the bottom line is crucial, choosing correctly can save time and money.

Avoid Common Bearings for Polyurethane Wheels Mistakes

Selecting a bearing for polyurethane wheels is not an easy task. This failure starts with a lack of the right kind of measuring. Without the correct size, a bearing could be too loose or too tight. A bearing that’s not snug enough might make the grinder wobbly, and a bearing that’s too tight could create excessive friction. Both can ruin your wheel. Then there is the mistake of not considering.. load. Each bearing can support up to a certain amount of weight. If you overburden it, it may break or wear out fast. Be sure to check Hanke's specs on the information page for a bearing that fits your profile. The environment in which you are going to use the wheels will further be a great factor. If the wheels will spend time in a dirty or wet environment, seek out bearings that are sealed to keep dirt and moisture at bay. Plus some forget to calculate how fast their wheel will be spinning. Special bearings are required for high-speed applications that can withstand the higher level of friction. Just keep in mind, it’s not a place to cut corners to save money little bit more investment for high end units will eventually pay off, because the cheaper ones also might not last that long or perform as good. Lastly, be sure to talk to professionals or manufacturers such as Hanke. We can provide you with guidance to avoid these common pitfalls.

What Influences The Bearing Fit In Polyurethane? Driven Wheels?

There are a number of variables involved in how bearings sit inside polyurethane driven wheels. It all begins with the bore of the wheel. The bore is the opening into which the bearing is placed. The bore will be too large or too small, and it can lead to issues. Additionally, the type of polyurethane found in the wheel can also influence fit. Various kinds of polyurethane may have negative or positive temperature and load effect. In other words, the bearing could fit differently under different conditions. Another key step is to know how much the wheel will bear. A heavy load requires a sturdier bearing and a tighter fit to keep everything in place. Application type also has an impact. You may also need a different fit if you use the wheel on rough surfaces than if you do so on smooth floors. Finally, the wheel speed also counts. Faster wheels require snugly fit bearings to prevent wobble or wear. So, while choosing your bearing for the polyurethane wheel all these factors are to be kept in mind. At Hanke, we support your thought process through each of these points to achieve an optimal solution.

How to Choose Better Bearings for Your Wheels

When picking the correct bearing for polyurethane driven wheels, take a moment to think about how you will use those wheels. This is a critical part that enables the wheel to run with less friction and smoother. Choose the wrong bearing, and your wheel won’t ride well or it might even break. Start by thinking on the load wheel will bear. Heavy loads require stronger bearings. Think of it as if you were picking the right shoes. If you’re going to race, you’ll need shoes that can handle your speed and weight. Likewise, the bearing also should be appropriate for the job of the wheel.

Next consider the wheel's speed. If the wheel is going to be spinning at a high rpms, you want your bearings to keep pace without burning up. Simply put, just as your bike wheel has special bearings to go fast, so does your polyurethane wheel. Also consider the setting in which you’re going to spin your wheel. If it’s in a wet or dirt-filled environment, you may want sealed bearings that keep out moisture and dust. It’s like putting on a raincoat on a rainy day; it keeps you dry and comfortable.

The fit between the bearing and the wheel is arguably just as important. That’s more or less the opposite of what a bearing is supposed to do. A well-fitted one stays put and keeps working. If the fit is too sloppy, there could be a wobble, and that’s no fun. If too tight, this can generate friction and therefore heat that makes the wheel less efficient. Hanke has several options when it comes to bearings and they can help you determine the best ones for use with your polyurethane wheels. By examining these conditions before choosing, you'll be choosing the best bearing that will enhance your wheel's performance and well last.

Where To Obtain Specialist Advice On Bearing Fits For Polyurethane Wheels

Not sure which bearing is the right one for your polyurethane wheels? There are all kinds of place where you can find expert advice. The internet is one wonderful place to look. Many websites offer valuable information for those wanting to learn more about polyurethane bearings what type you should get that fits your requirements, in particular. You can read articles, watch videos, and pop into forums where people share their experiences. Hanke’s website is also a good resource to begin. They offer a rich collection of guides and resources to enumerate all aspects about different bearing fits.

A second method is to ask professionals within the field. Localbearing or wheel sellers can be good alternatives as well. He or she has often had a lot of experience and can be very helpful in guiding you to the right thing. Don’t hesitate to ask it if you have questions of a specific nature. They’re here to help you get the best match for your polyurethane wheels. Another good way is to go to trade shows or industry events. T hose events usually also include people who know a whole lot about the topic at hand and would love to impart that knowledge.

But ultimately you may want to get in touch with Hanke himself. They have experienced people in the team who can help with the right advice that you need specifically. Whether you’re in the market for robust bearings to handle heavy or specialized ones built for speed, Hanke can help steer you through your options. Good advice will also help ensure that your wheels perform at their best, and you’ll be more confident knowing they were the right choice for you.

What Are Some Of The Emerging Trends And Innovations In Bearings For Industrial Applications?

Bearings are changing with the times and there are several interesting new trends that have developed in recent years, with just as many further trends predicted to revolutionise bearings - especially for industrial uses. One of the biggest trends involves new materials. Engineers are also experimenting with new materials that make bearings stronger and more lightweight. Some bearings, for example, are now constructed of special plastics or composites that are able to deal with heavy loads without adding extra weight. It’s akin to the way sports equipment has more and more progressed in becoming lighter and stronger over time. Hanke stays abreast of this development making sure their bearings are suitable for the modern industry.

The other major shift is the trend toward using smart technology. If our smartphones have changed our lives, smart bearings are starting to change the way we think about performance. These bearing wheels can be equipped with sensors that measure how they are working in real time. If there’s a problem, such as overheating or abnormal vibrations, they can alert you. This tech also keeps equipment from breaking and makes maintenance a breeze, saving time and money in the long run.

In bearing design there is also a growing emphasis on sustainability. Such advanced bearings would not only be efficient but also environmentally friendly. This might entail using recycled materials or producing bearings that last longer, thereby reducing waste. Hanke is really focused on sustainability and always pushing for ways to make their products more planet friendly. These advancements are not only for performance but for the good of our world. As we move on into the Mobile 16, it’s interesting where these trends will lead us and what affects they will have on industry.

Table of Contents

- Avoid Common Bearings for Polyurethane Wheels Mistakes

- What Influences The Bearing Fit In Polyurethane? Driven Wheels?

- How to Choose Better Bearings for Your Wheels

- Where To Obtain Specialist Advice On Bearing Fits For Polyurethane Wheels

- What Are Some Of The Emerging Trends And Innovations In Bearings For Industrial Applications?