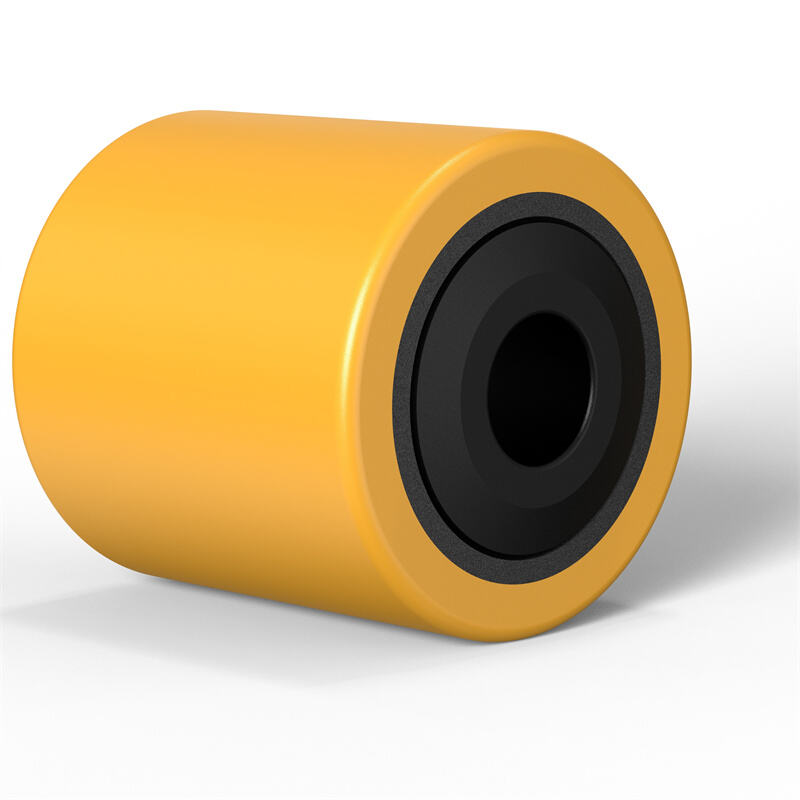

Determining whether to purchase smooth or treaded polyurethane drive wheels can seem tricky, but the following explanations will help you make the decision that’s best for your application. Hanke is here to guide you through what each type of wheel actually is. Treaded and smooth paws serve different functions. Understanding how they operate can have a huge impact on the performance of your equipment. In this article we will take you through things to think about when choosing the best wheel for your needs.

What are the Differences between Smooth and Treaded Polyurethane Drive Wheels?

Treaded and smooth polyurethane drive wheels have different features and applications. Flat They have smooth wheels on their underside allowing them to easily glide across sleek floors. They allow machines to change configuration easily with little resistance. It means that less energy is required to push or pull something. For instance if you have a cart that you’re pushing on planar on the wheels can make it go faster and more efficiently. If the floor is uneven, or if there are obstacles, smooth wheel surfaces may not grab effectively. They can slip and slide, so they are difficult to direct across surfaces for intentional movement.

On the other hand, treaded wheels have design patterns or grooves on their surface. These ribs give added surface contact when the ground is broken or crumbled. If your machines are on a bumpy warehouse floor, where debris can get in the way, treaded wheels might help them stay steady. They can stop slipping and ensure that your equipment stays in check. They’re also great for outdoors where the ground may be uneven or damp.

When choosing which type to use, consider where and how you'll be using the wheels. For applications that require pushing heavy loads fast over smooth floors, you might prefer smooth wheels. But if you want to navigate sandy or rough terrain, or you need better traction elsewhere, treaded wheels could be the way to go. Also keep in mind the weight of what you are carrying. If you plan on carrying heavier items, treaded wheels could be a source of more stability. Every wheel type has its pros and cons, so it’s best to consider your options thoughtfully.

Places to Get Great Deals on Polyurethane Drive Wheels for Wholesale Purchasers

If you’re purchasing polyurethane drive wheels in extremely large quantities, then you will be looking for great deals without compromising the quality of the product. Hanke is an expert in high-quality wheels at competitive prices, taking the hassle out of supplying wholesale customers with what they need. A wonderful place to begin your search is at manufacturing trade shows. These events are great for networking with suppliers and touching products in the flesh. These shows quite often have discounted or special offers.

You might also try to search online. Many, Hanke among them, offer wholesale pricing on their websites. You can shop around and score the best deals without ever leaving your living room. Definitely scour for reviews or ratings of the wheels. That way you know what you’re getting is reliable. You can also send suppliers a request. Ask them if they have any deals and discounts on bulk buying. In some cases, companies are willing to negotiate price for larger orders.

Don’t forget about local distributors. You may sometimes find lower prices on their products because you save the shipping fee. Establishing a relationship with a local supplier can help you receive better deals as time goes on. Always ask the warranties/guarantees on the products. This is to demonstrate that the company believes in what they are selling. Simply by doing these, you would be able to find best deals on polyurethane drive wheels suiting both your needs and budget.

When considering smooth vs treaded polyurethane drive wheel, it is critical to understand how each will affect your operation. Wheels with tread are ones where there are either patterns cut in the wheel or grooves. These patterns assist the wheel to hold the ground better. This can be very handy during heavy lifting or on a slick floor. On the contrary, smooth wheels are flat. They offer a smooth roll, which is particularly good if you want to glide something speedily across hardwood or stone floors. But they can be slippery when wet or on an uneven surface.

Choosing Between Treaded and Smooth Wheels: Factors to Consider for Performance and Longevity

Treaded wheels generally result in noise and additional wear. Some tread can generate more noise while rolling, which can be annoying in quiet environments. Also, if treaded wheels are used upon a very smooth surface for any length of time the wear is more rapid. This means you’ll need to replace them more frequently. Wheels that are smoother and quieter can slide on the floor if it is not level. Smooth wheels may not provide you with the amount of control that you need when moving things on a surface that’s not very rigid. This can be a huge problem in environments such as factories. So if you’re contemplating these wheels, consider where and how you’ll use them. If you have many ramps or need to stop suddenly, treaded wheels may be what you want. But if you’re sliding something in a straight line along a flat floor, smooth wheels can be your best friend.

Smooth vs. Treaded Polyurethane Drive Wheels: How to Choose Based on Surface, Load, and Performance

There are a few things to consider when trying to decide between smooth vs. treaded polyurethane drive wheels. First off, think about what surface you're going to be riding your wheels on. If you work a lot on rough or un-level floors, then treaded wheels will help give you more grip and control. If you plan to use the wheels only on smooth surfaces, such as tile or concrete, you might prefer smoother wheels. Next, consider the weight of what you are moving. Heavy loads may need wheels with treads for stability, while lighter items may be fine rolling on smooth wheels. Also, consider how quickly you have to move. If speed matters, smooth wheels can make it easier to go faster on flat surfaces. Although if you’ll be stopping aggressively or need to maneuver tight corners, grooved wheels are going to give you a ton more control. Finally, consider any noise concerns. If you're on smooth ground, you may want smoother-than-treaded wheels if noise is an issue you'll be less noisy on smooth ground with slippery grass, I find.

Guidelines for Choosing the Right Custom Polyurethane Wheels for Your Surface and Needs

Here are some guidelines that you can use to ensure that you’re using the correct custom polyurethane wheels surface. For starters, do a surface check to wherever you’ll be working. If they're smooth, you might want to give smooth wheels a try. If it's rough ground, maybe you should be using treaded wheels. Second, consider how heavy your loads are and what you will do with them. If you often have to transport heavy items wear and tear abraded wheels can help keep everything in place. Third, consider how quickly you want to go. Smooth wheels are your best bet for fast moves on smooth surfaces. Fourth, perhaps take a moment to consider what level of noise your workplace will comfortably tolerate. If you have to be discreet, your best bet is something with smooth wheels. Finally, don’t be afraid to ask for help! Experts at Hanke can help guide you in selecting the right wheels for you. By taking these aspects into account, you can get the most out of your machinery and simplify and secure your work.

Table of Contents

- What are the Differences between Smooth and Treaded Polyurethane Drive Wheels?

- Places to Get Great Deals on Polyurethane Drive Wheels for Wholesale Purchasers

- Choosing Between Treaded and Smooth Wheels: Factors to Consider for Performance and Longevity

- Smooth vs. Treaded Polyurethane Drive Wheels: How to Choose Based on Surface, Load, and Performance

- Guidelines for Choosing the Right Custom Polyurethane Wheels for Your Surface and Needs