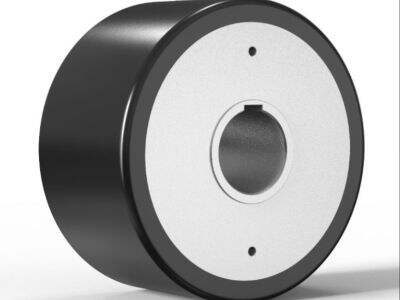

Delamination is when a polyurethane drive wheel’s layers begin to peel away or separate from each other. This can potentially cause the wheel to break prematurely and cease functioning correctly. At Hanke, we understand the frustration of dealing with broken wheels; especially when you need something that will give you long lasting performance in the tough jobs. Polyurethane is a tough material, but when it’s either formulated or treated improperly, delamination may occur. This post explains some useful methods to maintain your custom Polyurethane drive wheel. We want you to spend as much time as possible enjoying your wheels and not worrying about them falling apart prematurely.

Long Service Life Polyurethane Drive Wheels for Wholesale Users

Wholesale customers frequently want dozens of wheels that perform well for a long time. It starts by thinking about quality from the outset of getting the right wheels. Here at Hanke, we have our own special formula and a strict process to keep each custom polyurethane wheels attached firmly and at maximum strength. One of the more common is wheels with bad bond between layers or weak glue. This can lead to delamination with minimal use. We have experienced that using good raw materials and closely supervising the curing process can make this a non issue. And wheels that are snug on their axles prevent extra stress that would cause layers to delaminate. If you’re a wholesale buyer, it’s intelligent to see if the wheels have ever survived harsh tests before you buy. Another trick is to keep wheels in places without too much heat or dampness, which can weaken the glue inside the wheel. And as the wheels come round, inspect for any cracks or bubbles — these are weak spots. Purchasing from Hanke is committing to quality wheels, built with passion and meant to endure. We also educate buyers on how to properly use and store the wheels. That way, the wheels don’t get mucked up before they even begin doing work. The be all, end all isn’t just to pick the right wheel at any price, but also picking a product that carries on strong and saves money in the long run by not requiring frequent replacement. Wholesale buyers, then, should always budget in for quality and handling to keep their wheels operating effectively.

Tips for Avoiding Delamination in Polyurethane Drive Wheels

Your wheels will thank you if you treat them right and keep an eye on potential problems early. One key thing is to clean the wheels often, particularly if they become dirty from grease or chemicals. Dirt can wedge between layers and nudge them apart. We at Hanke ever found, using soft brush and mild soap give the best result without damaging the wheel coating. Another important consideration is to not shock or overload it. Polyurethane is durable, but hard smacks or overweight can cause the bond between layers to break. Some people do not remember to look at wheel alignment; uneven pressure can lead to peeling layers. We constantly recommend users to check wheels and axles on a regular basis. If you notice any of that sort of peeling or cracking, consider fixing or replacing the wheel before it breaks all the way. Temperature also matters. The glue can lose its stickiness in extremes of heat or cold. Keeping wheels in a dry, cool place will help preserve their strength. Ensure that the wheels are fitted correctly and do not apply a surplus of glue or bonding agent. Hanke’s team has to guide customers on the correct installation process, as small slip ups here lead to big problems down the line. Another reason for delamination is running wheels past the point of their design range. Each wheel has a specific speed and load limit. Disregarding these restrictions overloads the layers and results in failure. We recommend you to follow the specs printed on your wheel, or provided by our service center. And sometimes, wheels need a break. There is no rest for the wheels, and hot they get with continuous hard use; heat loosens the glue. Providing wheels with time to cool means they hold their strength longer. At Hanke, we think that understanding proper care and paying attention to detail helps stop delamination and keeps your polyurethane drive wheels rolling for years on end.

Wholesale Buyers Guide to Polyurethane Drive Wheel Wear Tolerance

When it comes to wholesale buyers, they are the ones that need to know how durable and long lasting these wheels can be. Polyurethane is great because it can take a beating and is frequently used for drive wheels. Hanke’s own polyurethane drive wheels certainly were built to last, however there are some details behind the scenes that will help a potential buyer make a good decision.

Durability is how well the wheel functions without breaking down or wearing out. Polyurethane is often used because it can withstand cuts, scrapes and rough surfaces better than a lot of other materials. This is critical for polyurethane wheels, which are rolling over all sorts of floors and surfaces. A go to work horse that will last through any job.

Hanke’s wheels are meticulously manufactured so that the polyurethane adheres well to the wheel core. This eliminates an issue of delamination, in which the polyurethane is separated from the wheel. If the wheel, it can crack or cease to function correctly, resulting in buyers having to spend money and time repairing or replacing wheels.

Wholesale purchasers should also be aware: The durability of wheels is in part a function of how they are used. The life of the wheel will be directly related to the quality of floor or surface over which it travels - wheels used on smooth floors under light load will last longer while wheels used on rough floors or under heavy loads will not wear as well. Hanke provides wheels meant for various uses. Shoppers select the appropriate wheel based on the weight of what is being rolled and the type of surface on which it will be rolling.

Knowing about the polyurethane drive wheels durability can help wholesale whereuse1rs make their choice in favor of Hanke’s products. Selecting a good strong wheel, well built, will lead to fewer issues, less downtime and actual savings. Whenever a buyer is in the market for a wheel purchase, they should inquire about how the wheel is made and what materials are used to achieve the best fit. And Hanke’s proprietary polyurethane drive wheels mean durability by design, to keep wheels rolling for a long time to come.

Effects of Temperature and Load on Delamination between Polyurethane Drive Wheels

In polyurethane drive wheels, temperature and load considerations are two of the most significant problems that can be attributed, including delamination. Delamination occurs when the polyurethane layer begins to pull away or split from the wheel core. Knowing how heat and weight impact the wheels can help offset delamination and out-of-whack wheels.

Excessive heat or cold can alter the properties of polyurethane drive wheels. From high temperatures is polyurethane eventually soft and viscose. This softness can also result in the bond between the polyurethane and the wheel core weakening and the two separating. Very low temperatures, on the other hand, can cause the polyurethane to become hard and brittle. And if you smash it against something hard, or in its cold state laden down with a heavy cargo, the wheel may crack (or break completely). The wheel loses its strength due to both heat and cold.

Load is how much weight that wheel has on it. The pressure on the polyurethane can cause it to stretch and separate from the core if a wheel is bearing more weight than intended. The polyurethane is driven down hard by the heavy loads, and if the bond is poor or if it is too hot or too cold for the material in use, that layer can begin to lift away. In the long term this peeling causes delamination and the wheel becomes unsafe and worthless.

Reasons Why Polyurethane Drive Wheels Delaminate and How to Prevent It?

Delamination occurs in polyurethane drive wheel when the poly layer strips or peels away from the core. This issue can interrupt the functioning of the wheel and make machinery go haywire. It is a helpful information to have as it lets you know what causes delamination of these wheels and how can they be fixed, which is something anyone using or planning on buying these wheels will benefit from. Hanke has been able to help many customers avoid these issues through proper design and simple solutions.

The problem with most delamination as already noted is bad adhesion between polyurethane and the wheel core. But if the materials are not well-prepared, or you’re lacking some of that glue vigor, the layers refuse to stick. Hanke averts this by meticulously cleaning the core and employing high-strength adhesives during production. This step is crucial, a weak bond won’t last long; i. e. poor durability – very poor durability if you’re going to use them everyday or most days thereof.

It's also the result of using the wheel inappropriately. For instance, the wheel can get dinged up and damage it and therefor have the polyurethane tear right off. If you load too heavily on the wheel, or if the wheel encounters an unexpected blow, polyurethane can crack or detach. This can be avoided with some decent right-wheeled wheels.

Table of Contents

- Long Service Life Polyurethane Drive Wheels for Wholesale Users

- Tips for Avoiding Delamination in Polyurethane Drive Wheels

- Wholesale Buyers Guide to Polyurethane Drive Wheel Wear Tolerance

- Effects of Temperature and Load on Delamination between Polyurethane Drive Wheels

- Reasons Why Polyurethane Drive Wheels Delaminate and How to Prevent It?