93 Брег А

добро

Веома добро

Неисплаћено

Пролаз: Квалитетни полиуретански еластомер који се лива хемијском реакцијом има тврдоћу од 93±3 Шор А. Има низак ниво буке при кретању, мали отпор котрљања, штити подлогу, високо је отпоран на хабање, има висок отпор на резање и трзање, не оставља трагове, не боји и има изузетан ефекат приливања за језгро точка.

Jezgra kolovoža: Метални материјали као што су челик 45#, ливено гвожђе, алуминијумски легуре под притиском и нерђајући челик могу се бирати у зависности од радних услова. Опције обраде површине укључују бојење, фосфатирање, цинкање, Дакромет итд

Остале карактеристике: Otporan na koroziju različitim korozivnim supstancama; Radna temperatura: -30°C do +70°C, kratkoročno do +90°C. Nosivost opada iznad +40°C

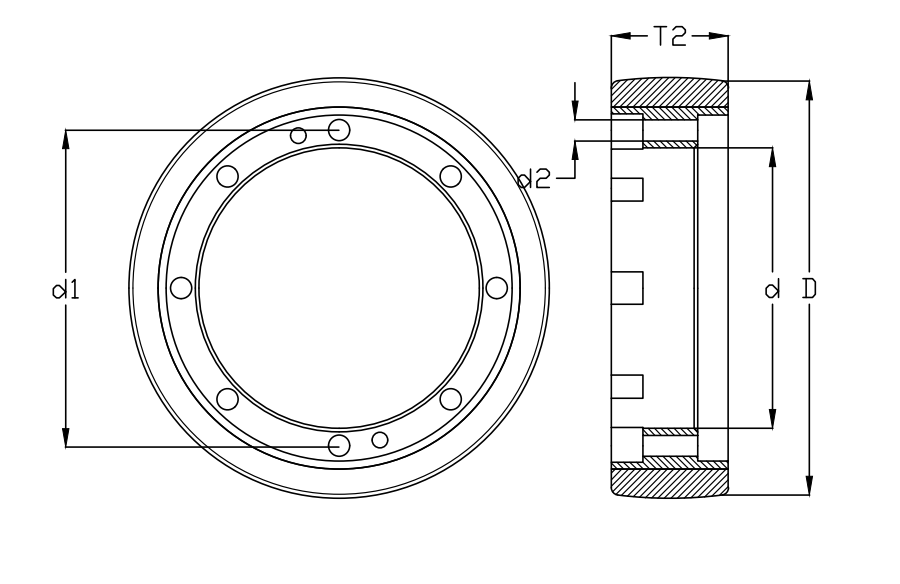

| Jedan kotač | Prečnik jednog točkova (D) {MM} |

Ширина једног точкова (T2) {MM} |

Nosivost pri 4 km/h [kg] |

Nosivost pri 10 km/h [kg] |

Nosivost pri 16 km/h [kg] |

Број Монтажење рупа |

Дијаметар монтажење рупе (d2) [mm] |

Дијаметар средње рупе (d) [mm] |

ПЦД (d1) [mm] |

||||||||||

| GEFC 200/50 | 200 | 50 | 900 | 630 | 360 | Доступно прилагођавање | |||||||||||||

| GEFC 250/60 | 250 | 60 | 1300 | 910 | 520 | Доступно прилагођавање | |||||||||||||

| GEFC 250/80 | 250 | 80 | 1600 | 1100 | 640 | Доступно прилагођавање | |||||||||||||

| GEFC 300/90 | 300 | 90 | 2100 | 1450 | 840 | Доступно прилагођавање | |||||||||||||

| GEFC 400/100 | 400 | 100 | 3400 | 2350 | 1350 | Доступно прилагођавање | |||||||||||||

| Питање за друге величине је добродошло | |||||||||||||||||||

Prednost poliuretana je u tome što se prilagodbom formule poliuretana može menjati njegova tvrdoća, boja, koeficijent trenja itd., kako bi se postigli efekti smanjenja buke, antistatičnosti i zaštite poda. Njegov dug vek trajanja i niske troškove održavanja čine da ukupna ekonomska isplativost bude visoka. Mogu se koristiti u različitim sredinama, kao što su hrana (bez zagađenja), provodni (za elektronske radionice) i visoko opterećeni (za luke opremu).

Možemo prilagoditi odgovarajuće poliuretanske točkove prema vašim zahtevima. U normalnim uslovima, maksimalna nosivost može dostići 10 tona, a maksimalna brzina do 10 kilometara na sat.

Да, можемо прилагодити формулу полиуретана како би испунио различите захтеве.

Опсег тврдоће полиуретанских материјала обично се креће између Шоре 70A и Шоре 100D. Полиуретански материјали веће тврдоће имају бољу носивост и отпорност на хабање, док полиуретански материјали ниже тврдоће омогућавају бољу заштиту подлоге и ефекте смањења буке.

Сви параметри се могу прилагодити према вашим потребама.

Подржавамо нпр. алуминијумска, челична, нилонска средишта

Минимална количина наруџбе је 10 комада. Време испоруке је обично 25 дана.

Подржавамо процес исправљања, али тражимо да платите одговарајуће накнаде.

Уколико дође до одламбања или пукотина у року од 24 месеца, обезбедићемо безнаплатну замену.