ပေါလီယူရီသိန်း စက်နင်းဘီးများ

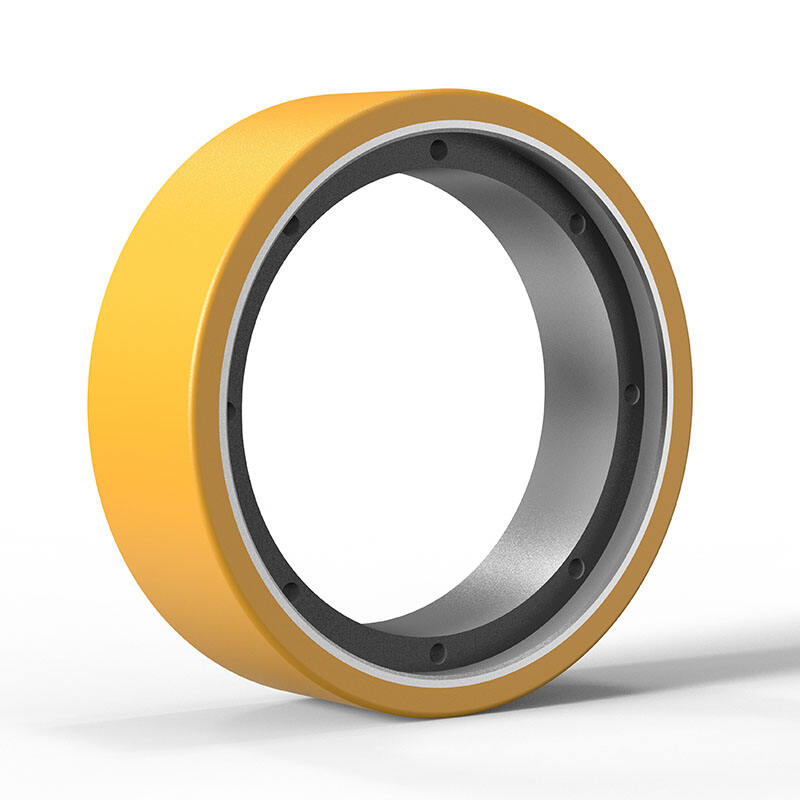

ပေါလီယူရီသိန်း စက်နင်းဘီးများ၏ စက်မှုလုပ်ငန်းအသုံးချမှုများသည် စက်မှုလုပ်ငန်းအများစုတွင် အရေးပါသော အခန်းကဏ္ဍမှ ပါဝင်ပါသည်။ ၎င်းတို့သည် ဝန်အလေးများကို လွယ်ကူစွာ လှည့်ပတ်ရာတွင် ကူညီပေးပြီး ပွတ်တိုက်မှုကို လျော့နည်းစေပါသည်။ သို့သော် စက်နင်းဘီးအားလုံးသည် တူညီခြင်းမရှိပါ။ အချို့သည် ဘူတာပြုလုပ်ထားသော သံကြိုးများဖြင့် ပြုလုပ်ထားပြီး ထိုဘီးများသည် ဝန်အလေးများအတွက် အလွန်ကောင်းမွန်ပါသည်။ Hanke သည် ဤအချက်ကို ကောင်းစွာသိပါသည်။ ကျွန်ုပ်တို့သည် အရည်အသွေးမြင့်မားပြီး polyurethane drive wheel ခိုင်ခံ့ပြီး ခံနိုင်ရည်ရှိသော ပစ္စည်းများကို ထုတ်လုပ်ရောင်းချပါသည်။ ဘူတာပြုလုပ်ထားသော သံကြိုးများ၏ အရေးပါမှုကို အသေးစိတ်လေ့လာကြည့်ပါမည်။ ထိုပစ္စည်းများကို အများအပြားရယူရန် မည်သည့်နေရာတွင် ရှာဖွေနိုင်မည်ကိုလည်း သိရှိပါမည်။

အထူးပြု ယူရီသိန်း မောင်းနှင်ရေး ဘ wheels များနှင့် သံကြိုးများ၏ အရေးပါမှု

CI အခြေခံများအပေါ်တွင် ယူရီသိန်း မောင်းနှင်ရေး ဘီးများသည် စံပြဖြစ်ပါသည်။ အဓိကအကြောင်းရင်းတစ်ခုမှာ ခိုင်မာမှုဖြစ်ပါသည်။ သံကြိုးသည် ခိုင်ခံ့ပြီး အလေးချိန်များစွာကို ခံနိုင်ရည်ရှိပါသည်။ ကုန်စည်များ၊ စက်ကိရိယာကြီးများ သို့မဟုတ် အတုံးလိုက်စီထားသော ဘူးများကဲ့သို့ ဝန်အလေးများကို သယ်ဆောင်ရသည့်အခါ သံကြိုးအခြေခံသည် ဘီးကို ကွေးခြင်း သို့မဟုတ် ပြိုကွဲခြင်းမှ ကာကွယ်ပေးပါသည်။ ထို့ကြောင့် ဘီးသည် ပိုမိုကြာရှိန်းစွာ အသုံးပြုနိုင်ပြီး ပိုမိုကောင်းမွန်စွာ လုပ်ဆောင်နိုင်ပါသည်။ ပလပ်စတစ်ပျော့ပျောင်းဖြင့် ပြုလုပ်ထားသော ဘီးများဖြင့် ဝန်အလေးကို သယ်ဆောင်ရာတွင် ကားပေါ်မှ လဲကျခြင်းမှ ကာကွယ်ရန် ကြိုးစားကြည့်ပါ။ ထိုဘီးများသည် ပို၍ ကွဲအက်ခြင်း သို့မဟုတ် အလွယ်တကူ ပျက်စီးခြင်းများ ဖြစ်နိုင်ပါသည်။ သို့သော် သံကြိုးအခြေခံများဖြင့် ပြုလုပ်ထားသော ဘီးများသည် ခိုင်ခံ့စွာ တည်ဆောက်ထားပြီး အသုံးပြုမှုများစွာကို ကောင်းစွာ ခံနိုင်ရည်ရှိပါသည်။

သံချေးမတက်သောအထည်များကို နှစ်သက်ရသည့် အခြားတက်လည်းဖြစ်ပါသည်။ အထူးသဖြင့် တိကျသော လှုပ်ရှားမှုများလိုအပ်သည့် စက်များအတွက် အထူးသင့်တော်ပါသည်။ ဘီးလှည့်နေစဉ် တုန်ခါမှုရှိပါက ပြဿနာဖြစ်စေနိုင်ပါသည်။ ဥပမာ - ထုတ်ကုန်များကို တစ်နေရာမှ တစ်နေရာသို့ သယ်ဆောင်နေသည့် ကွန်ဗီယာဘဲလ်တွင် ဘီးလှည့်နေပါက ခိုင်ခံ့သော ဘီးသည် အရာအားလုံးကို တိကျစွာ လည်ပတ်စေပါသည်။ ဟန်ကေ၏ ဘီးများသည် သင့်တော်သည့် နည်းလမ်းဖြင့် လှည့်ပတ်နိုင်ရန် သံချေးမတက်သော အထည်ကို အသုံးပြုထားပြီး စက်ရုံများနှင့် ဂိုဒေါင်များတွင် မကြာခဏ အသုံးပြုကြပါသည်။

သံချေးမတက်သော အထည်သည် အပူကိုလည်း ကောင်းစွာ ခံနိုင်ရည်ရှိပါသည်။ ဘီးများ လှည့်ပတ်နေစဉ် အပူချိန်မြင့်တက်လာတတ်ပြီး အထူးသဖြင့် ဝန်အများကြီး သယ်ဆောင်နေစဉ်တွင် ပို၍ပင် ဖြစ်ပါသည်။ ထိုအပူကို စီမံခန့်ခွဲရန် လိုအပ်ပြီး သံချေးမတက်သော အထည်သည် ထိုလုပ်ငန်းကို ဆောင်ရွက်ပေးကာ ဘီးများ အလွန်အမင်း မပျက်စီးစေပါ။ ထို့ကြောင့် ဟန်ကေသည် ပေါလီယူရီသိန်း မော်ဒယ်များအတွက် ဘီးများတွင် သံချေးမတက်သော အထည်ကို အသုံးပြုရန် တောင်းဆိုပါသည်။ ထိုသို့ပြုလုပ်ခြင်းဖြင့် ဘီးများအား အပိုကာကွယ်မှုပေးကာ သက်တမ်းကို ရှည်စေပြီး နောင်တွင် ငွေကို ခြွေတာနိုင်ပါသည်။

နောက်ဆုံးတွင် သံချောင်းအကြိုးများသည် လုံခြုံရေးအတွက်လည်း ကောင်းမွန်ပါသည်။ ဘီးတစ်ခုခု ကျိုးသွားပါက စက်ရုံများကဲ့သို့ လူများထူထပ်သော ပတ်ဝန်းကျင်များတွင် မတော်တဆဖြစ်မှုများကို ဖြစ်ပေါ်စေနိုင်ပါသည်။ ဘီးတစ်ခု ကျိုးသွားပါက ဝန်ပိုးတစ်ခုလုံး ကျရောက်သွားခြင်း သို့မဟုတ် စက်တစ်ခု ရပ်တန့်သွားခြင်းများ ဖြစ်နိုင်ပါသည်။ သံချောင်းအကြိုးများကဲ့သို့ ခိုင်မာသော အကြိုးများဖြင့် ထိုကဲ့သို့ဖြစ်နိုင်ခြေများမှာ အများကြီး နည်းပါးပါသည်။ ထို့ကြောင့် သံချောင်းအကြိုးများပါသော ဘီးများကို ရွေးချယ်ခြင်းသည် ဉာဏ်ရည်မီသော ဆုံးဖြတ်ချက်သာမက လုံခြုံသော ဆုံးဖြတ်ချက်လည်း ဖြစ်ပါသည်။

ပေါ်လီယူရီသိန်းဘီးများအတွက် သံချောင်းအကြိုးများကို တင်ပို့ရောင်းချမည့်နေရာ

ပေါ်လီယူရီသိန်းဘီးများအတွက် သံချောင်းအကြိုးများကို ဝယ်ယူလိုပါက Hanke သည် ကောင်းမွန်သော ရွေးချယ်စရာတစ်ခုဖြစ်ပါသည်။ အများအပြားဝယ်ယူပါက စျေးသက်သာမည့် တင်ပို့ရောင်းချမှု ရွေးချယ်စရာများကို ကျွန်ုပ်တို့တွင် ရရှိနိုင်ပါသည်။ သင့်အသုံးပြုမှုအတွက် သင့်တော်သော အကြိုးများကို ရှာဖွေရာတွင် ကျွန်ုပ်တို့၏ ဝန်ထမ်းများက ကူညီပေးနိုင်ပါသည်။ ကျွန်ုပ်တို့၏ ဝက်ဘ်ဆိုက်ကို စစ်ဆေးကြည့်ရှုခြင်း သို့မဟုတ် ကျွန်ုပ်တို့နှင့် တိုက်ရိုက် ဆက်သွယ်ခြင်းများ ပြုလုပ်နိုင်ပါသည်။ ကျွန်ုပ်တို့၏ ထုတ်ကုန်များနှင့် စျေးနှုန်းများအကြောင်း အားလုံးကို သင့်အား မျှဝေပေးနိုင်ပါသည်။

သင့်အနေဖြင့် ကိုယ်တိုင်မေးခွန်းထုတ်မိပါလိမ့်မည်။ ပမာဏများများဝယ်ယူပါက ယူနစ်တစ်ခုလျှင် ပိုမိုကောင်းမွန်သော စျေးနှုန်းကို ရရှိတတ်ပါသည်။ လိုအပ်သည့် ဘ wheels အရေအတွက်များစွာကို အဆင်သင့်ထားရှိရန် လိုအပ်သော စီးပွားရေးလုပ်ငန်းများအတွက် ငွေကို ခြွေတာနိုင်ပါသည်။ သင့်တွင် အသုံးပြုရန်အတွက် အဆင်သင့်ဖြစ်နေသော သံကြိုအချောင်းများ ရှိနေပါက ၎င်းတို့ ပျက်စီးသွားမည်ကို စိုးရိမ်ရန် မလိုအပ်တော့ပါ။

သင့်အတွက် မှန်ကန်သော ပေးသွင်းသူကို ရွေးချယ်ရန် အရေးကြီးပါသည်။ အရည်အသွေးနှင့် ဝန်ဆောင်မှုအတွက် လူသိများသော ထင်ရှားသည့် အမှတ်တံဆိပ်ကို ရွေးချယ်ပါ။ Hanke တွင် ကျွန်ုပ်တို့ ထုတ်လုပ်သော အရည်အသွေးမြင့် ထုတ်ကုန်များအတွက် ကျွန်ုပ်တို့ အသိအမှတ်ပြုခံရပါသည်။ ကျွန်ုပ်တို့၏ သံချောင်းများသည် စက်မှုလုပ်ငန်းအတွင်း အကောင်းဆုံးများအဖြစ် ရပ်တည်နေကြောင်း ဂုဏ်ယူစွာ ပြောဆိုနိုင်ပါသည်။ ထို့ကြောင့် ကျွန်ုပ်တို့ထံမှ သင်ဝယ်ယူပါက မှန်ကန်သော ရွေးချယ်မှုကို ပြုလုပ်နေကြောင်း သင်ယုံကြည်စိတ်ချနိုင်ပါသည်။

စျေးနှုန်းနှင့် အရည်အသွေးအပြင် ပို့ဆောင်မှုကာလကိုပါ စဉ်းစားသင့်ပါသည်။ မြန်ဆန်သော ပို့ဆောင်မှုသည် သင့်ဘီးများကို ဖွင့်လွတ်သော လမ်းပေါ်သို့ အမြန်ဆုံးရောက်ရှိစေပါလိမ့်မည်။ Hanke သည် မှာယူထားသမျှကို အချိန်မီရရှိစေရန်အတွက် သင့်အား အကောင်းဆုံးပေးသွင်းနိုင်ရန် အတွက် အာရုံစိုက်လုပ်ဆောင်နေပါသည်။

ပေါလီယူရီသိန်းဘီးများအတွက် သံချောင်းအကြိုးများကို စုစည်း၍ဝယ်ပါ။ ပေါလီယူရီသိန်းအတွက် သံချောင်းအကြိုးများသည် မောင်းနှင်ရေးဘီးများ လုပ်ငန်းတိုင်းအတွက် ဉာဏ်ရည်ထက်မြက်သော ရင်းနှီးမြှုပ်နှံမှုဖြစ်ပါသည်။ သင့်အားငွေကိုခြွေတာပေးပြီး အလုပ်ကိုမြန်မြန်ဆန်ဆန်လုပ်ဆောင်နိုင်ရန် လိုအပ်သမျှကို သေချာစေပါသည်။ Hanke သည် သင့်အား အဆင့်တိုင်းတွင် ကူညီပေးပါလိမ့်မည်။ သေးသည်ဖြစ်စေ၊ ကြီးသည်ဖြစ်စေ၊ လုပ်ငန်းအမျိုးအစားတိုင်းအတွက် ကျွန်ုပ်တို့တွင် ဖြေရှင်းနည်းရှိပါသည်။

ထို့ကြောင့် ပြဿနာများနှင့်တွေ့ကြုံနေရသော ပေါလီယူရီသိန်း မောင်းနှင်ရေးဘီးများ၏ အသုံးဝင်မှုများမှာ အဘယ်နည်း။

ပေါ်လီယူရီသိန်း ဒရိုက်ဘီးများသည် ခိုင်မာပြီး အလေးချိန်များစွာကို ထမ်းဆောင်နိုင်သောကြောင့် ရေပန်းစားကြခြင်းဖြစ်သည်။ သို့သော် စိန်ခေါ်မှုများသော အခြေအနေများတွင် အသုံးပြုပါက အခက်အခဲများကို ရင်ဆိုင်ရနိုင်ပါသည်။ အသုံးအများဆုံးပြဿနာတစ်ခုမှာ မျက်နှာပြင်များ မညီညာသော မြေပြင်များတွင် အသုံးပြုပါက ဤဘီးများသည် အလွယ်တကူ ပျက်စီးတတ်ခြင်းဖြစ်သည်။ ဘီးများသည် မြေပြင်ပေါ်ရှိ မြှောက်နှံ့များ သို့မဟုတ် အပေါက်များကို ဖြတ်သန်းသွားပါက ပေါ်လီယူရီသိန်းပစ္စည်းမှ ဖြစ်ပေါ်လာသော ဓားထက်ဖြင့် ပြတ်တောက်သွားနိုင်ပါသည်။ ဤပျက်စီးမှုများသည် ဘီးများကို သံမဏိခြေထောက်ပုံ ပြောင်းသွားစေပြီး လွယ်ကူစွာ လှည့်ပတ်နိုင်ခြင်းကို တားဆီးနိုင်ပါသည်။ နောက်ထပ်ပြဿနာတစ်ခုမှာ ပေါ်လီယူရီသိန်းဘီးများကို ကာလကြာမြင့်စွာ အသုံးပြုခြင်း (သို့) အလေးချိန်များစွာကို သယ်ဆောင်ပါက ၎င်းတို့သည် ပူလာနိုင်ခြင်းဖြစ်သည်။ ဤအပူဓာတ်သည် ပစ္စည်းပျက်စီးမှုကို ပိုမိုမြန်ဆန်စေနိုင်ပါသည်။ စက်ရုံများ သို့မဟုတ် ဂိုဒေါင်များကဲ့သို့သော နေရာများတွင် ဘီးများကို သေးငယ်သော လှည့်ခြင်းများအတွက် အသုံးပြုပါက ကားတစ်စီးကဲ့သို့ပင် ပြားခြင်းများ ဖြစ်ပေါ်လာနိုင်ပါသည်။ ဘီးသည် မြေပြင်ပေါ်တွင် တစ်နေရာတည်းတွင် အချိန်ကြာရှည်စွာ ရပ်နေပြီး တစ်ခုခုသော အပိုင်းသည် အခြားအပိုင်းများထက် ပိုမိုပျက်စီးသွားသောအခါ ပြားခြင်းများ ဖြစ်ပေါ်လာပါသည်။

ဤပြဿနာများသည် လှုပ်ရှားမှုနှေးကွေးခြင်းနှင့် ၎င်းတို့နှင့် ချိတ်ဆက်ထားသော စက်ကိရိယာများအပေါ် သက်ရောက်မှုတို့ကို ဖြစ်ပေါ်စေနိုင်ပါသည်။ ဘ� wheels များ ပျက်စီးပါက စက်များ အလုပ်မလုပ်နိုင်တော့သည့် အချိန်များ ဖြစ်ပေါ်စေနိုင်ပါသည်။ ဤကဲ့သို့ အလုပ်မလုပ်နိုင်သည့် အချိန်များသည် ကုမ္ပဏီများအတွက် အလွန်ကုန်ကျစရိတ်များပါသည်။ ဤပြဿနာအများစုကို အနည်းဆုံးဖြစ်အောင် လုပ်ဆောင်ရာတွင် သင့်တော်သော ဘီးများသည် အရေးပါပါသည်။ Hanke တွင် ဤအချက်ကို ကျွန်ုပ်တို့နားလည်ပြီး သင့်ထုတ်ကုန်များ ပိုမိုကြာရှည်စွာ အသုံးပြုနိုင်ပြီး ခက်ခဲသော ပတ်ဝန်းကျင်များတွင် ပိုမိုကောင်းမွန်စွာ လည်ပတ်နိုင်ရန် ဖြေရှင်းနည်းများကို ကျွန်ုပ်တို့ ပေးအပ်လိုပါသည်။ ဥပမာ - ပေါလီယူရီသိန်း မောင်းနှင်ရာဘီးများတွင် သံလိုင်းအကျိုးများ အသုံးပြုခြင်း။

ဘာကြောင့် အလွန်အမင်း ဝန်ထမ်းသော အသုံးချမှုများအတွက် သံလိုင်းအကျိုးပါသော အိုင်းဒက်(ခ်)တာများကို အသုံးပြုကြသနည်း။

ပေါလီယူရီသိန်း မောင်းနှင်ရာဘီးများသည် သံလိုင်းအကျိုးများ အသုံးပြုခြင်းကြောင့် အလွန်ခံနိုင်ရည်ရှိအောင် ပြုလုပ်ထားပါသည်။ ဘီး၏ သံလိုင်းအကျိုးသည် ပိုမိုလေးသော ဝန်ကို သယ်ဆောင်နိုင်ပြီး တိုက်ခတ်မှုနှင့် ပွတ်တိုက်မှုများကို ပိုမိုခံနိုင်ရည်ရှိပါသည်။ ဤအချက်သည် စက်ရုံများ သို့မဟုတ် ဂိုဒေါင်များကဲ့သို့ ပုံမှန်အားဖြင့် လေးသော ပစ္စည်းများကို သယ်ဆောင်နေသည့် နေရာများတွင် အလွန်အရေးပါပါသည်။ သံလိုင်းသည် ဝန်ကို သယ်ဆောင်ရန် အသုံးပြုနိုင်သော ဘီးအတွက် ခိုင်မာသော အထောက်အပံ့လည်း ဖြစ်ပါသည်။

သံချောင်းအကြိုးနှင့်တကွ ထားရှိပါက ၎င်းသည် မြေပြင်ကို ကပ်ငြိနေမည်ဖြစ်ပြီး ဝိုင်းလည်ခြင်းသည် ဝန်အလေးခံနေစဉ်တွင်ပါ တည်ငြိမ်စွာ လည်ပတ်နိုင်ရန် ပြုလုပ်ထားပါသည်။ ပေါ်လီယူရီသိန်းသည် ပျော့ပြီး ဘီးများသည် ထိခိုက်မှုများနှင့် တုန်ခါမှုများကို စုပ်ယူစဉ်ကာလအတွင်း မာကျောသော သံချောင်းနှင့်အတူ အသုံးပြုပါသည်။ ဆိုလိုသည်မှာ ပစ္စည်းကိရိယာများ ကောင်းစွာလည်ပတ်စေရန်နှင့် ဘီးများ သို့မဟုတ် ၎င်းတို့ကို တပ်ဆင်ထားသော စက်ကိရိယာများကို ပျက်စီးစေခြင်းမှ ကာကွယ်ရန် အရေးကြီးပါသည်။

ထို့အပြင် သံချောင်းသည် ခံနိုင်ရည်ရှိပြီး အသုံးပြုစဉ်တွင် အလွယ်တကူ မပျက်စီးပါ။ ဒါကြောင့် စိုးရိမ်ဖွယ်ရာ ပတ်ဝန်းကျင်တွေမှာတောင် သံဘီးတွေရဲ့ သက်တမ်းရှည်ကြာမှုကို ဖြစ်စေပါတယ်။ စွမ်းဆောင်ရည်ကို ရှည်ကြာစေမည့် ပိုက်ဆံပုံဖြစ်ခြင်း သို့မဟုတ် ပုံပျက်ခြင်းတို့ကို ဖြစ်ပေါ်နိုင်ခြေ နည်းပါးပါသည်။ Hanke တွင် အဆင့်မြင့်စွမ်းဆောင်ရည်ဖြင့် အလုပ်လုပ်သော ထုတ်ကုန်များကို ဒီဇိုင်းထုတ်ရန် ဂုဏ်ယူပါသည်။ ပေါ်လီယူရီသိန်း မောင်းနှင်ရေး ဘီးများတွင် သံချောင်းအကြိုးများ အသုံးပြုခြင်းသည် ဤအရာကို အကောင်အထည်ဖော်ရန် ကျွန်ုပ်တို့ အသုံးပြုသော နည်းလမ်းများအနက် တစ်ခုဖြစ်ပါသည်။

သံချောင်းအကြိုးပါ ပေါ်လီယူရီသိန်း မောင်းနှင်ရေး ဘီးများကို ဘယ်လိုရွေးချယ်မလဲ။

ရွေးချယ်ရန် ပေါ်လီယူရီသိန်း မောင်းနှင်ရေး ဝိုင်း သံချောင်းများပါဝင်သော ဘီးများအတွက် အချက်များစွာကို ထည့်သွင်းစဉ်းစားရန် လိုအပ်ပါသည်။ သို့သော် ပထမဆုံးတွင် ဘီးများက ထမ်းဆောင်ရမည့် ဝန်အလေးချိန်ကို ဆွေးနွေးသင့်ပါသည်။ အစိတ်အပိုင်းများတွင် ပါဝင်သော ဘီးများသည် ဝန်အလေးချိန်များ ကွဲပြားနိုင်ပြီး ဝန်အလေးချိန်များဖြင့် အစိတ်အပိုင်းများကို ရွှေ့ပြောင်းရန် လိုအပ်ပါက သင်မျှော်လင့်ထားသော ဝန်အလေးချိန်ကို ထမ်းဆောင်နိုင်သည့် ဘီးများကို ရွေးချယ်ရန် လိုအပ်ပါသည်။

ထို့နောက် ဘီးများ ပြေးလွှားမည့် မျက်နှာပြင်ကို ကြည့်ပါ။ သို့မဟုတ် မတည်ငြိမ်သော သို့မဟုတ် မျက်နှာပြင်မျက်နှာပြင်များရှိပါက သင့်လိုအပ်ချက်ကို ဖြည့်ဆည်းပေးနိုင်မည့် ဘီးများ လိုအပ်နိုင်ပါသည်။ သင့်တွင် သံချောင်းများပါသော ဘီးများ မရှိသေးပါက ၎င်းတို့သည် ခက်ခဲသော မျက်နှာပြင်များကို ခံနိုင်ရည်ရှိသောကြောင့် ကောင်းမွန်သော ရွေးချယ်မှုဖြစ်ပါသည်။ ဘီးကို အသုံးပြုမှု မကြာခဏ အသုံးပြုမှုကိုလည်း သင်စိတ်ဝင်စားပါလိမ့်မည်။ နေ့စဉ်နေ့တိုင်း တစ်နေ့လုံး ပြေးလွှားရန် လိုအပ်ပါက ၎င်းတို့သည် သူတို့၏ တာဝန်ကို ထမ်းဆောင်နေကြောင်း သိရှိလိုပါလိမ့်မည်။

ဘ wheels အကွာအဝေးသည် တစ်ခုအရေးပါသော ထည့်သွင်းစဉ်းစားရမည့်အချက်ဖြစ်သည်။ ပို၍ကြီးမားသော ဘီးများသည် ပို၍သေးငယ်သော ဘီးများထက် အတားအဆီးများကို ပိုမိုကောင်းမွန်စွာ ဖြတ်သန်းနိုင်ပြီး နေရာတိုင်းတွင် မကျင်လည်နိုင်ပါ။ ထို့ကြောင့် သင့်တော်သော လိုအပ်ချက်များနှင့် ကိုက်ညီမည့် အရွယ်အစားကို ရွေးချယ်ရန် အထူးတန်ဖိုးရှိပါသည်။ Hanke သည် ၎င်းတို့၏ ထုတ်ကုန်ကို ဂုဏ်ယူပြီး သင့်အသစ်ဝယ်ယူမှုအတွက် ကောင်းမွန်သော အာမခံချက်ကို ပေးသည့် တစ်ခုတည်းသော ကုမ္ပဏီမဟုတ်ပါ။ ထို့ကြောင့် သင်သည် အားရကောင်းမွန်စွာ ရင်းနှီးမြှုပ်နှံနေကြောင်း သိရှိပြီး စိတ်ချယုံကြည်စွာ နေထိုင်နိုင်ပါသည်။ သင့်လိုအပ်ချက်များနှင့် အကောင်းဆုံးကိုက်ညီမည့် သံချောင်းအချောင်းပါသော ပေါ်လီယူရီသိန်းဘီးများကို ရှာဖွေရာတွင် ကူညီပေးရန်အတွက် စွမ်းဆောင်ရည်နှင့် အသုံးပြုမှုတို့ကို ပိုမိုကောင်းမွန်စေမည့် ထည့်သွင်းစဉ်းစားရမည့် အချက်များကို ဤစာရင်းတွင် အသေးစိတ်ဖော်ပြထားပါသည်။

အကြောင်းအရာများ

- ပေါလီယူရီသိန်း စက်နင်းဘီးများ

- အထူးပြု ယူရီသိန်း မောင်းနှင်ရေး ဘ wheels များနှင့် သံကြိုးများ၏ အရေးပါမှု

- ပေါ်လီယူရီသိန်းဘီးများအတွက် သံချောင်းအကြိုးများကို တင်ပို့ရောင်းချမည့်နေရာ

- ထို့ကြောင့် ပြဿနာများနှင့်တွေ့ကြုံနေရသော ပေါလီယူရီသိန်း မောင်းနှင်ရေးဘီးများ၏ အသုံးဝင်မှုများမှာ အဘယ်နည်း။

- ဘာကြောင့် အလွန်အမင်း ဝန်ထမ်းသော အသုံးချမှုများအတွက် သံလိုင်းအကျိုးပါသော အိုင်းဒက်(ခ်)တာများကို အသုံးပြုကြသနည်း။

- သံချောင်းအကြိုးပါ ပေါ်လီယူရီသိန်း မောင်းနှင်ရေး ဘီးများကို ဘယ်လိုရွေးချယ်မလဲ။